In this blog, I’d like to tell you about a classic MPS innovation that is well received by our customers worldwide: the Ultraflex rail system. In my territory of Russia and surrounding countries, this system is a popular part of many press sales.

Here’s why.

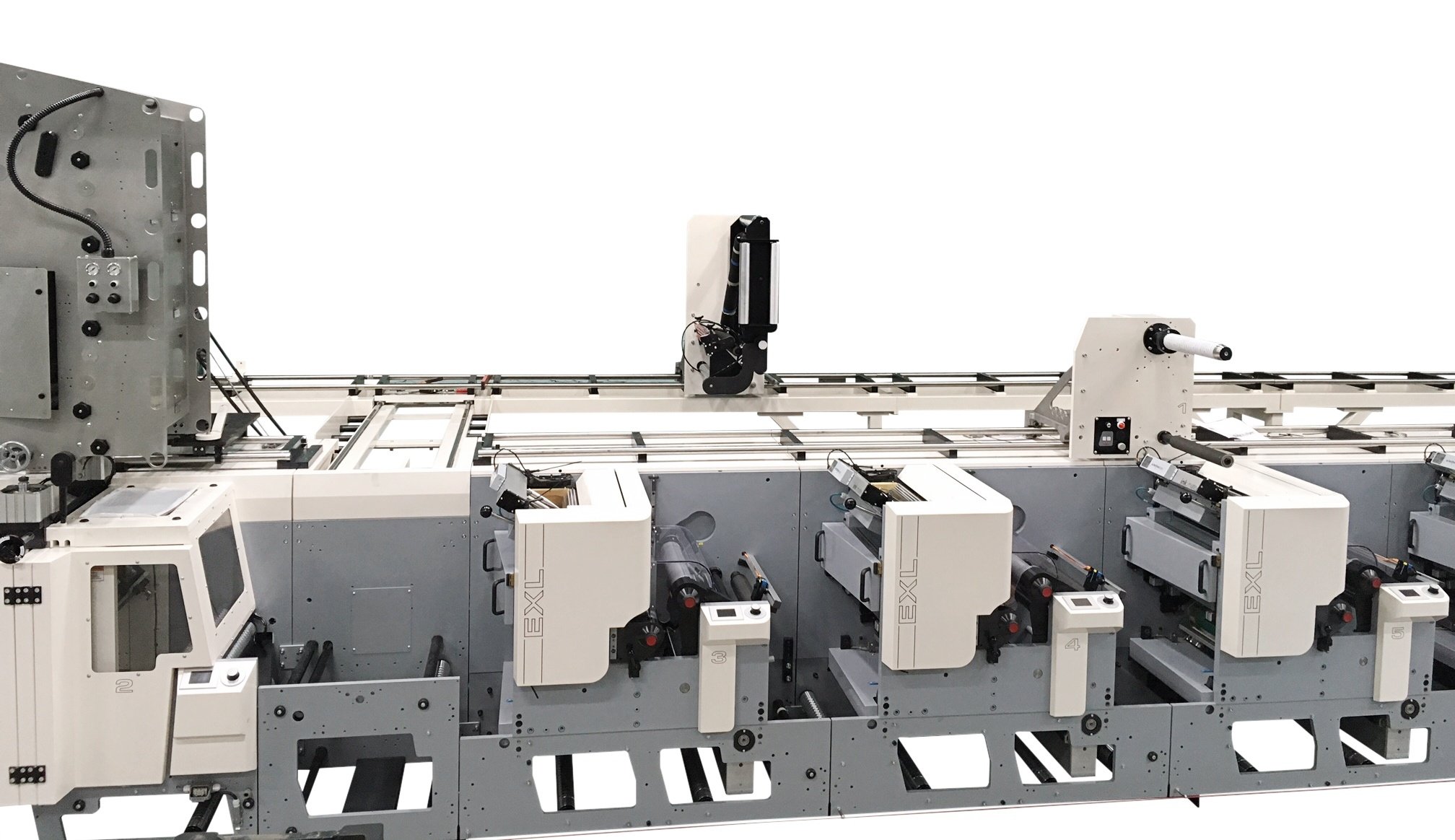

To save time, energy, and money, MPS developed the innovative rail system. Equipped with every MPS flexo press, this system provides great flexibility when positioning your rail units.

Place a web turner bar on print unit 2, a cold foil application on print unit 6, or a screen print unit in between — everything is possible. Thanks to the rail system’s ergonomic design, it’s also easy to slide a rail unit to a different position.

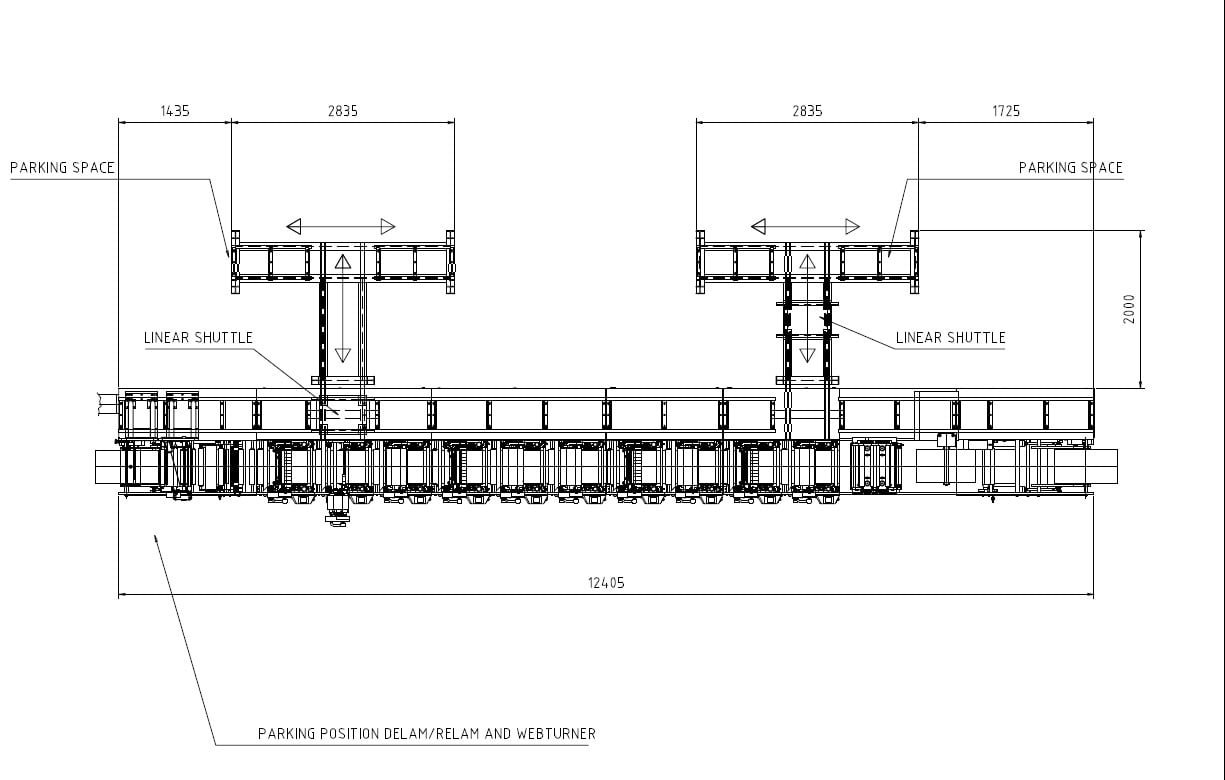

And then there’s an even higher level of flexibility with the Ultraflex rail system, to quickly move and store rail units. With T-shaped rails behind the machine, rail units can be moved to any position without taking them off the press. Unused units can be easily stored behind the press while waiting for their next job.

One of our customers requested a system to connect five(!) MPS presses, resulting in the biggest Ultraflex system ever. Now, they can easily shift rail units from one press to another, without the need of a hoist to remove the units. And the huge time saved in set-up means more time to print labels.

The MPS Ultraflex rail system offers the ultimate in flexibility. Would you like to know more or curious about other MPS printing innovations? Contact me or your local MPS representative!