With growing competition in the label printing industry, your goal is to print labels as quickly as possible at the lowest cost.

It is fair to say that an inefficient printing process, long lead times, and errors are no-go areas. When you print labels that are mostly similar but differ in some respects — for example, a different image or barcode — variable data printing (VDP) is a smart way to efficiently print high-quality labels that meet your customers (lead-time) requirements.

In this blog, I’ll explain further.

What is variable data printing?

In short, variable data printing is a type of digital printing in which elements such as text, images, and graphics can change from one printed label to the next. This technique doesn’t stop or slow down the printing process and uses information from a database or PDF file.

Some examples of variable data printing are address labels, unique codes like QR-codes, barcodes or lottery codes, and images.

Three methods of variable data printing

Here are three examples of variable data printing:

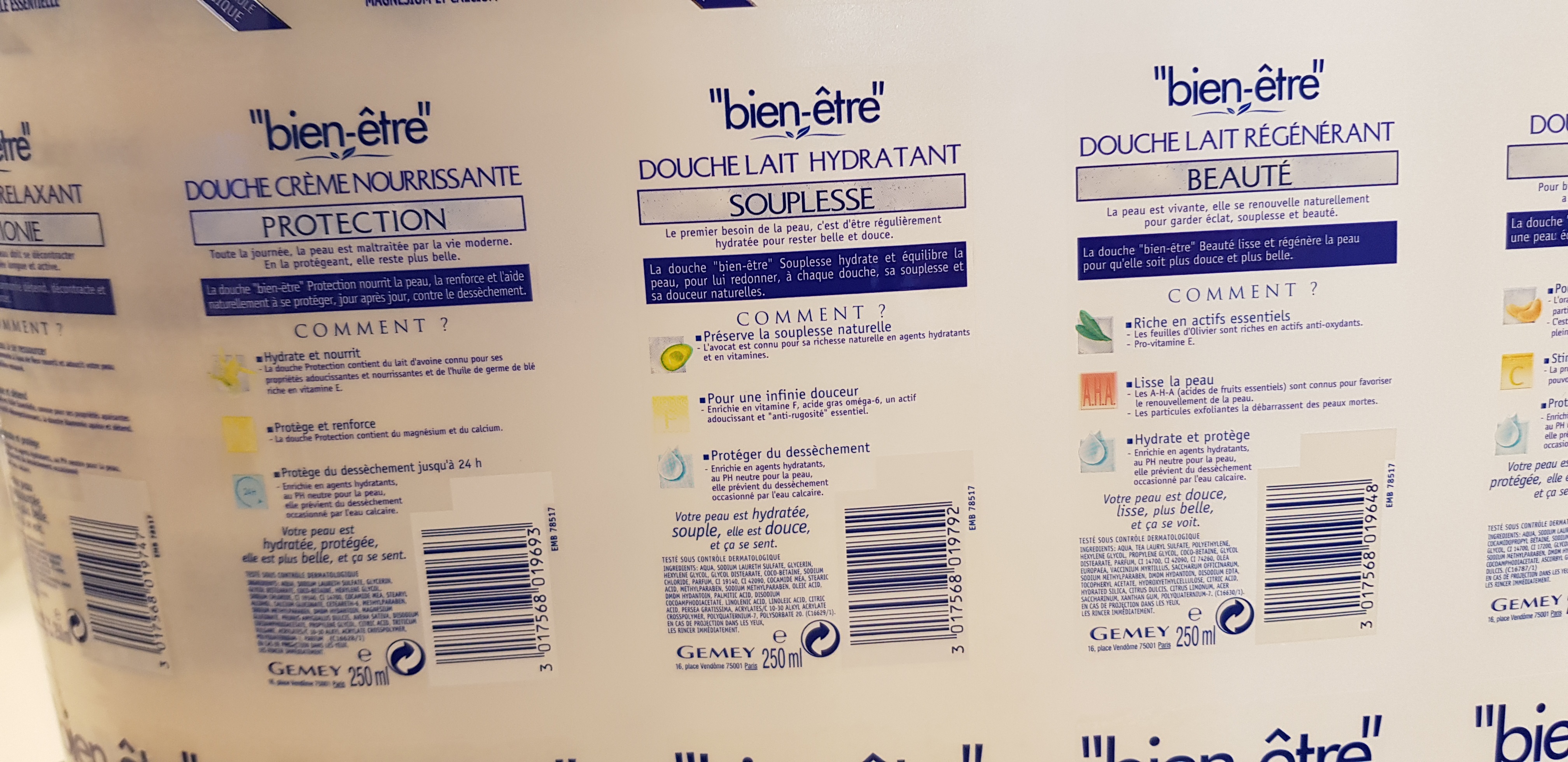

- Variation in images

As with the World Cup in Russia in June and July, imagine the endless possibilities of labels for a targeted marketing campaign. For example, there are twenty-three images available of each player in your nation’s squad, and you want a different player on each label. Therefore, you need to print 23 PDF files in a loop. This is how variable data printing makes this a possibility.

- Variation in codes

Do you need to print labels with a unique code, such as bar or QR codes? Not a problem with variable data printing.

Let’s say you have 100 different codes: you will need 1 PDF with 100 pages (each with a different code) to get the output you require.

- Smart fields in PDFs

If you need an extended number of labels with a different code, such as lottery tickets, then creating 1 PDF with X number of pages or creating many single PDF files is no longer efficient. Ideally, you want to extract information from a database automatically.

To do so, you need one PDF file with a smart field that is connected to a database. The connection between the PDF file and your database doesn’t just help you to work more efficiently and win more time in the prepress stage; you can also print these numbers randomly.

Variable data printing vs. in-line finishing

Depending on what kind of labels you need to print, variable data printing is an incredibly efficient way to print customized labels. However, in digital printing it is common that the finishing of the label, such as die-cutting, lamination, varnishing or slitting, is done on separate machines.

Off-line finishing increases the risk of errors and delays because printing and converting are separate processes. If something goes wrong in the converting process, you need to start a job again. The principle in variable data printing is that everything must go well at once, otherwise it becomes a very complex process.

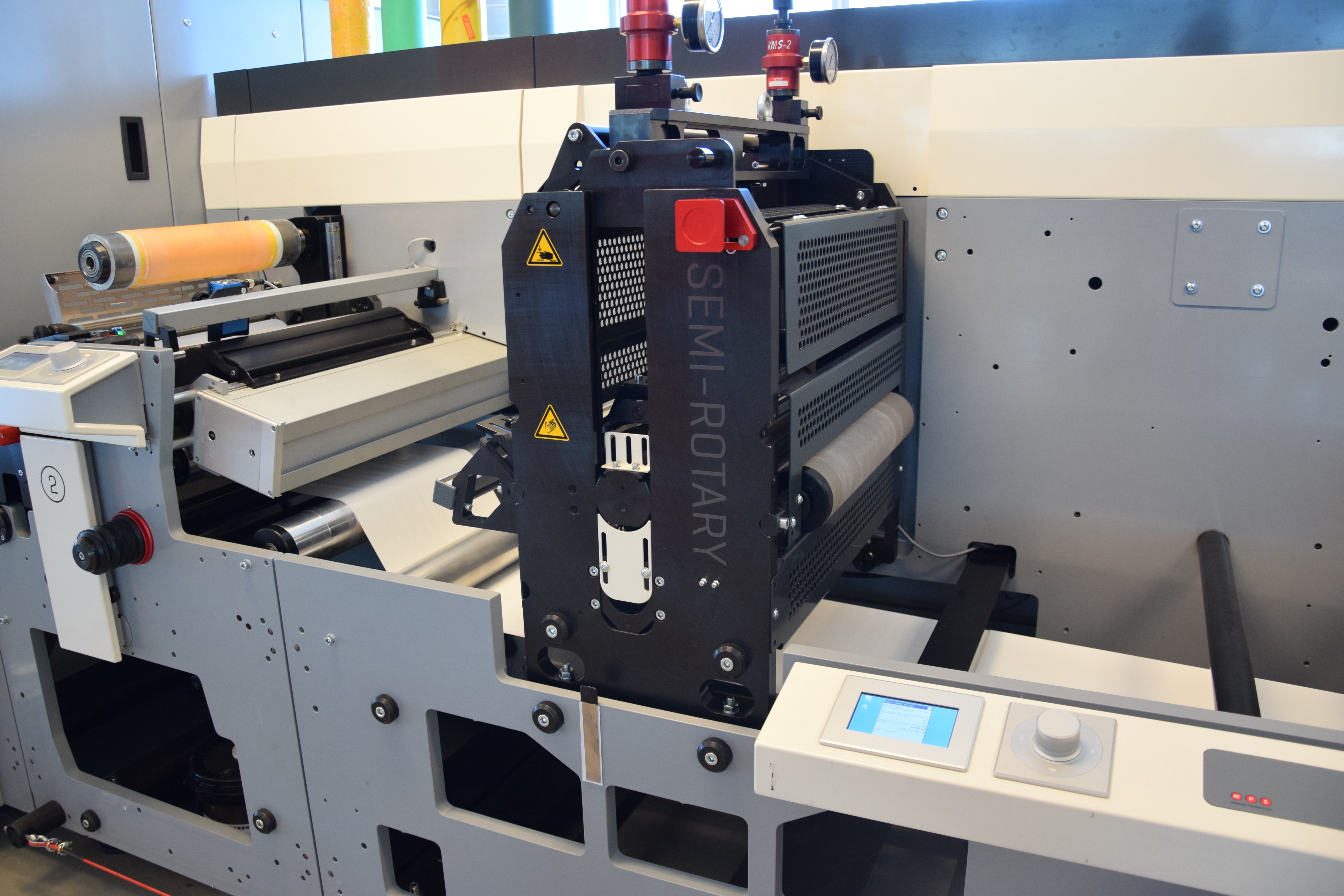

This is where hybrid printing — combining several printing technologies and converting techniques in a single-pass process — comes in. Because adding in-line finishing to your digital printing process is not as easy as merely placing an in-line finishing unit on your press. You need a combination with flexo printing to enable this opportunity.

Semi-rotary die cutting on the MPS EF SYMJET hybrid press

Semi-rotary die cutting on the MPS EF SYMJET hybrid press

On narrow web presses; laminating, die-cutting, varnishing, and adding applications such as cold foil can only be done in flexo printing. In a hybrid press, the converting can be done in-line. You can have completely printed and finished labels, just in one pass!

Learn more in our free whitepaper about hybrid printing

So in short, to fully enable the benefits of variable data printing and ensure short lead times and low costs, a hybrid printing press is favourable. However, is hybrid printing a viable solution for your business? Find out in this whitepaper.