Earlier this month I was in the bustling city of Bangkok, speaking at the Shift_018 Conference about connectivity - the Internet of Things (IoT), Industry 4.0 - and the impact this will have on the label and packaging industry. If you're curious about my presentation, you can download it here.

The conference was a two-day event bringing together thought leaders and experts from around the world, where Suwannee Tantisrisuk and I met with many dynamic label printers and MPS suppliers. We also had the opportunity to attend the 2018 Packaging & Print Awards where Miss Universe Thailand presented many of the accolades!

Regarding connectivity….is your organization ready for the challenges and opportunities it will bring?

Are YOU ready?

Living in a connected world

The world is changing, and we are living in a more connected way than ever before. Connectivity will be an integral part of the printing process, with processes already in place and rapidly moving forward.

Next generations, especially the iGeneration/Generation Z are growing up in this connected world with digital technology and the internet engrained in their way of life. These tech-savvy, multi-taskers already have a significant impact on how businesses operate and market their product.

Connectivity, IoT & Big Data need to be a starting point for any new development within your company. It must become part of your culture.

Where your printing press is headed

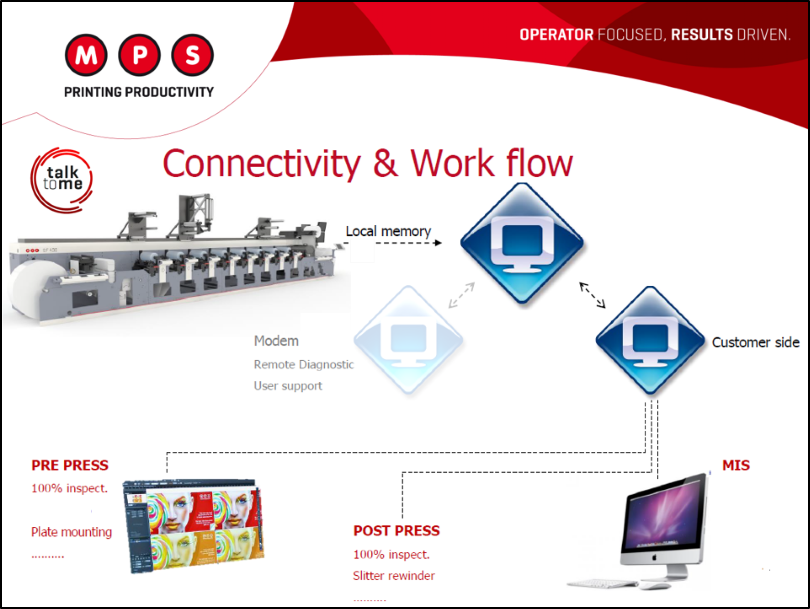

The printing press will be a part of a total networked/connected environment and part of your overall process. It is no longer a stand-alone press. Thanks to internet developments and sensor technology, we can connect the press with the management information system (MIS), prepress systems and talk to the machines and their components within.

Because of this connectivity, you can follow and find jobs and send machine settings to the equipment you use to produce a label. The press will be connected in a network with the MIS, prepress, job memory, service, purchasing, logistics, work preparation and more. The production environment of the future will become transparent.

In itself, this concept is not new at all. For years we’ve been hearing about the networked production environment: think Cip3 and later Cip4. These developments have now only accelerated because of the internet and sensor technologies.

Benefits and new opportunities with connectivity

Because your MIS, prepress, press and finishing are all connected in workflows, you have the following benefits:

- Real-time production status

- No paperwork

- Clear (historical) data

- Less downtime

- Detailed insights in performances

- Optimization of resources

- Maximum operational results

- Overall improvement of your equipment effectiveness

You now know what the cost price per label is, whether the planned schedule is going to be met, if a job is running on the calculated speed, and waste figures — all from the data generated by your press.

Data creates new opportunities in potential earning models. Pay per use, pay per time or even pay per label will come in reach, using this data-driven management.

The press becomes the vehicle for new developments and further integration of new business models.

Embracing a new mindset

Connectivity will certainly change our printing industry in a very big way.

The biggest challenge I see is the mindset of people. How can company owners, managers, operators stay on top of all these developments, understand and implement it? This is a huge task.

Technology does not care whether you are ready. Forward-looking competitors hope you aren’t ready. The fourth industrial revolution is already underway. It’s critical to your business to understand this and make small investments step-by-step.

Accept, Create, Invest

It’s important to accept that connectivity, IoT and Big Data is here already. This is not a trend that will pass.

Create a strategy to implement connectivity and include all functions in the organization.

And subsequently, invest in the infrastructure and talent that will support this.

But don’t try to implement everything in one go. Just go step-by-step.

The first step should be the one step to stay ahead.

Start small, but…start now!

Interested in my presentation?

Download my presentation here:{{cta('5b304325-1062-4534-b5b3-f31f5e715b91')}}