If you’re a flexo-based label printer/converter, you may be wondering if it’s the right time to get started with digital. You may be wondering when to use flexo and when to use digital. And what about hybrid?

Let’s take a closer look at these technologies to help get the answers.

Flexography is a printing technology that has been around for decades. Flexographic label printing is an ideal choice for longer runs with a minimal number of SKUs. Why? Since flexo uses printing plates and inks that must be changed for each specific job requirement, it’s best to have the press running continuously for as long as possible. When one SKU or version of a label is printed and completed, it then takes additional time and labor to complete the setup, or makeready, of the next job to print—changing colors, plates, etc. And during that makeready downtime, when the press is not running, the label printer/converter is not making money.

When to use flexo printing technology?

So, longer runs with minimal changes are best for flexo. In addition, flexo allows for embellishments to be added to labels, and printing and finishing is combined in a single process.

When is digital printing the best solution?

Digital printing is an ideal choice for short run work, jobs that require multiple SKUs, multiple versions, frequent graphic changes or when variable data is required. Digital printing provides consistency in production with computerized color management, so label to label, job to job, the colors are consistent and repeatable with no variation between operators.

Makeready time, cost, inventory, waste and material are minimized, and digital printing provides an efficient way to handle shorter to moderate run lengths, while providing the flexibility to finish inline or near-line. From an efficiency standpoint, many label printer/converters are looking at digital to complement their flexo label printing business.

When to choose for hybrid printing?

Flexo and digital have long been thought of as competing technologies, but in reality, they should be thought of as complementary technologies. Especially since customers have more choices th

an ever before and brand owners do everything to grab and hold their attention.

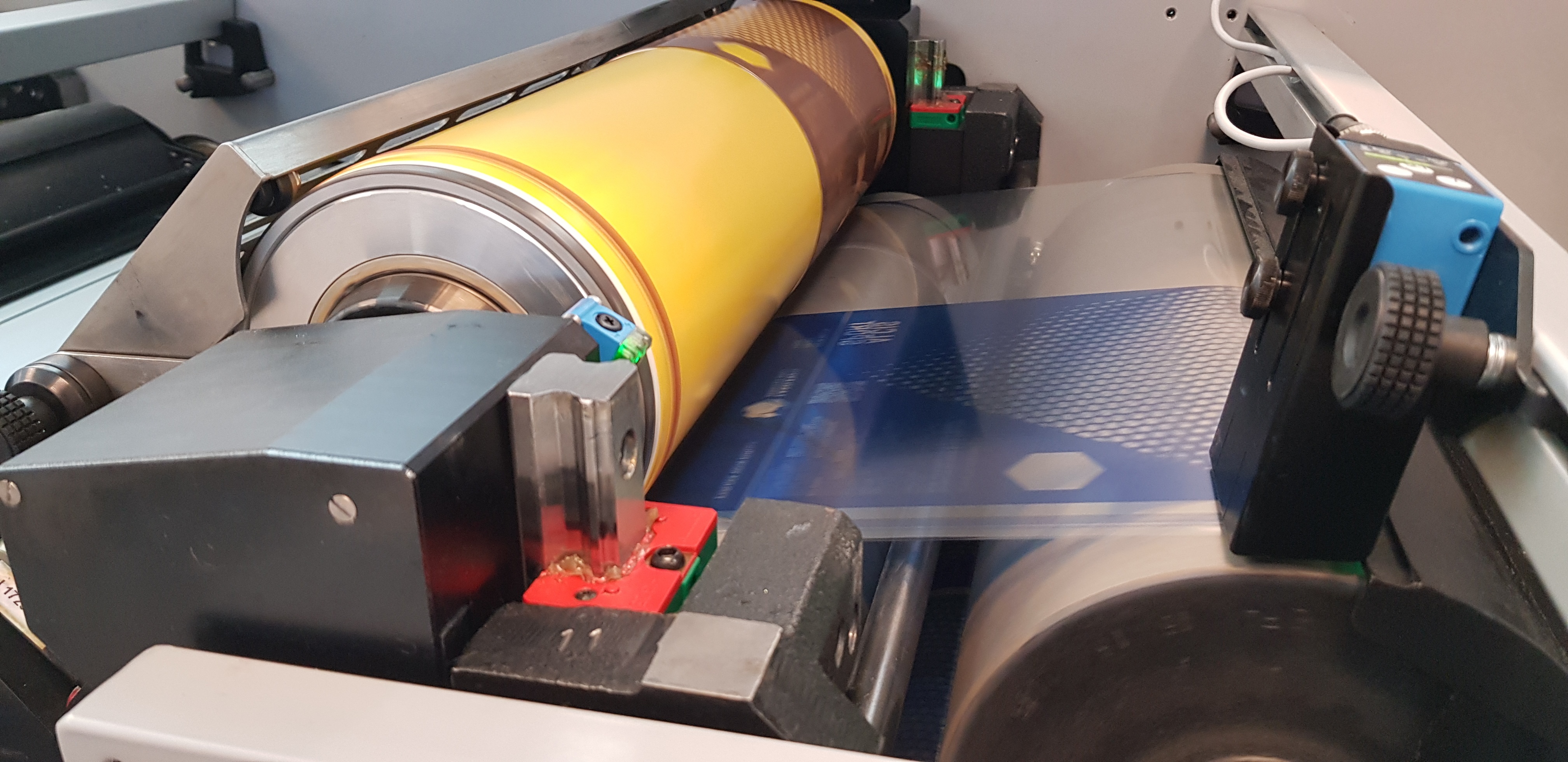

Hybrid label printing combines flexo and digital, bridging the gap between the two technologies, offering unlimited options for inline printing and converting. It’s a platform for producing longer runs and higher label counts, and provides the option of adding embellishments, spot colors, varnishes and more while maintaining the consistency, repeatability and efficiency benefits that digital brings. Hybrid integrates the best attributes of flexo and digital.

Minneapolis-based Meyers invested in the MPS EF SYMJET 7-color digital UV inkjet hybrid label press that will allow it to deliver a much larger variety of premium print treatments at lower costs to its customers. The decision to purchase was driven by the company’s desire to advance its digital offering. “The addition of the hybrid press to our operation has provided the biggest positive impact on our business that we have seen in the last 10 years,” says Gregg Temple, president of Meyers Label and Card Groups.

You might also like to read:

Meyers is the first in North America to purchase the MPS EF SYMJET press, powered by Domino

When considering whether to go with a digital-only or hybrid configuration, “It is important for the label converter to assess its current workload and future opportunities to really determine which digital platform is the best fit. If the majority of its work and opportunities do not involve metallic colors, hot or cold foil stamping, or other embellishments, it does not make sense to consider a hybrid approach,” said my colleague Chuck Stone, senior account manager with Domino. “A hybrid press will require a different skill level operator due to the other technologies on the platform, and you won’t get the full savings in increased production time and lower material waste of straight digital.”

Flexo and digital: this and that

As said, flexo and digital have long been thought of as competing technologies, but in reality they should be thought of as complementary technologies. The forward-thinking label printer/converters have figured this out, utilizing the appropriate technology based on the job requirements at hand. So, when thinking about flexo or digital, just remember—it doesn’t have to be “this or that.” It can be “this and that.” It’s an exciting time—make certain you don’t get left behind!

Download free whitepaper about hybrid printing

{{cta('2aaef802-c0d6-4640-9bb7-48d5f26bb664','justifyright')}}Want to know more about hybrid printing? Download MPS’ free whitepaper here and discover if hybrid printing is the right solution for your company.

This is a guest blog by Bill Myers, Marketing Manager Digital Printing at Domino North America

.