When printing labels or flexible packaging, the process of drying the ink is an essential part that has a big impact on the quality of the result. Due to price, technological or legal reasons, several printers use water-based (WB) or solvent-based (SB) inks.

Choice of hot air dryer is essential for drying WB and SB inks. Not only the speed, but also the quality of the final product highly depends on that. Unfortunately, the choice for a hot air dryer is sometimes neglected or made in a “check” manner. What exactly are hot air dryers?

Hot air drying primarily involves the evaporation of water-based and solvent-based inks – which occurs as heated air circulates over and around the surface being dried.

High air velocity dryers

There are various types of hot air dryers available on the market that differ in technology, length, temperature, and more.

After experimenting over a long period of time with different technologies, MPS chose high air velocity dryers to integrate with our printing presses. With these dryers, air velocity reaches up to 120 meters per second to increase efficiency and speed.

This technology is designed on two important factors for drying WB

and  SB inks – correct temperature and speed of removing

SB inks – correct temperature and speed of removing

evaporated particles from above the web. Important here is not

the amount of air, but the speed of it running through the air

nozzles. During development of this technology, the velocity of air

in the dryer was increased up to the speed of sound!

What are the main advantages of high velocity dryers?

1) Far less amount of air in the system

2) Faster and more efficient removal of vapours

3) Up to 80% less energy consumption

4) Lower temperature compared to conventional dryers

Explosion safety

For all solvent printing stations, we deliver an ATEX certification, as solvent inks have a high risk of explosion danger. [link to Koen’s blog about ATEX that will be published next week).

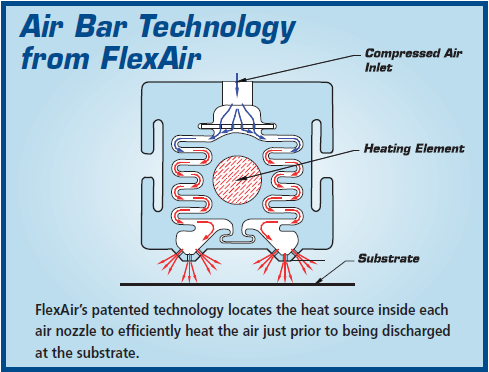

Heating element inside the dryer

Our high velocity dryers have a heating element inside the dryer instead of in the machine. The advantage? When you start the printing process, the heating element already warms up the dryer, which means you can immediately start drying.

Our high velocity dryers have a heating element inside the dryer instead of in the machine. The advantage? When you start the printing process, the heating element already warms up the dryer, which means you can immediately start drying.

With other types of dryers (with heating elements in the machine), a lot of substrate material will go through the press while the dryers are still cold. On temperature sensitive materials like shrink foil, this could be disastrous.

New type of dryer

A year ago, we introduced a new type of hot air dryer: Type A. This dryer increases line speeds and lowers operating costs. Many other advantages include:

• The dryers are built in the machine instead of on the rail, which means the rail is free for units like cold foil or varnishing.

• It’s easier to work with, due to the ergonomic height and ease of putting through material.

• The design of the dryer is modified with the use of the latest 3D flow calculation to provide the most efficient air flow in the system.

• For example, water-based primer brought on BOPP foil with an anilox of 9 gram/m2 can be dried at the speed of 220 metres (721 feet) per minute, due to these integrated dryers and a short web path.

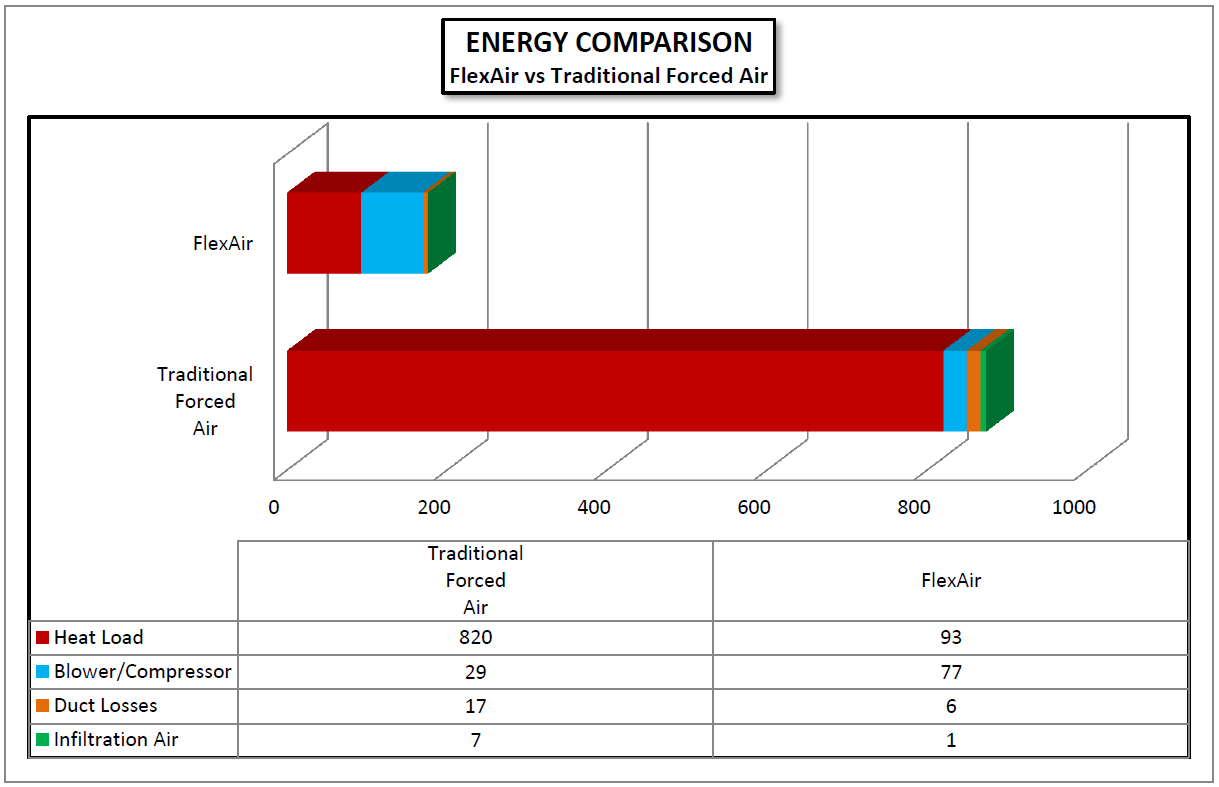

Below, you will find a comparison of our air dryer (produced by FlexAir) compared to traditional forced air dryers. As you can see, the heat load is considerably lower in terms of energy.

Source: FlexAir Innovative Drying Solutions

Source: FlexAir Innovative Drying Solutions

Combining hot air dryers with UV dryers

It’s always possible to combine hot air dryers with UV dryers, or even LED dryers, in one printing station. This means you can use both UV, water-based and solvent inks in one press for different technologies.

The best solution

Each case, product, application, substrate, and ink require different types of drying. Feel free to contact us to assist you with the right selection.

We can provide interstation dryers from 0,4 meters to 3,4 meter rail dryers with several temperature zones, and the best solution for working speeds up to 300 meters per minute.