In the label industry, there are mainly two factors that determine which printing technique is best for your company: quality and cost price. With many technologies to choose from, it may sometimes be hard to determine which technology fits your business best.

As every printing job requires a different set of needs, there are several factors to be taken into account when choosing the right printing technology.

Two technologies that are often compared are letterpress and flexo printing. In this blog, I’ll explain the way those two technologies work, and list some advantages and disadvantages of both.

The classic letterpress technology

Letterpress printing: the process explained

Letterpress printing is a relief printing process that initially utilized raised metal type and engravings to imprint words and designs on a page. It originated in the 1400s and was the primary form of printing for over 500 years.

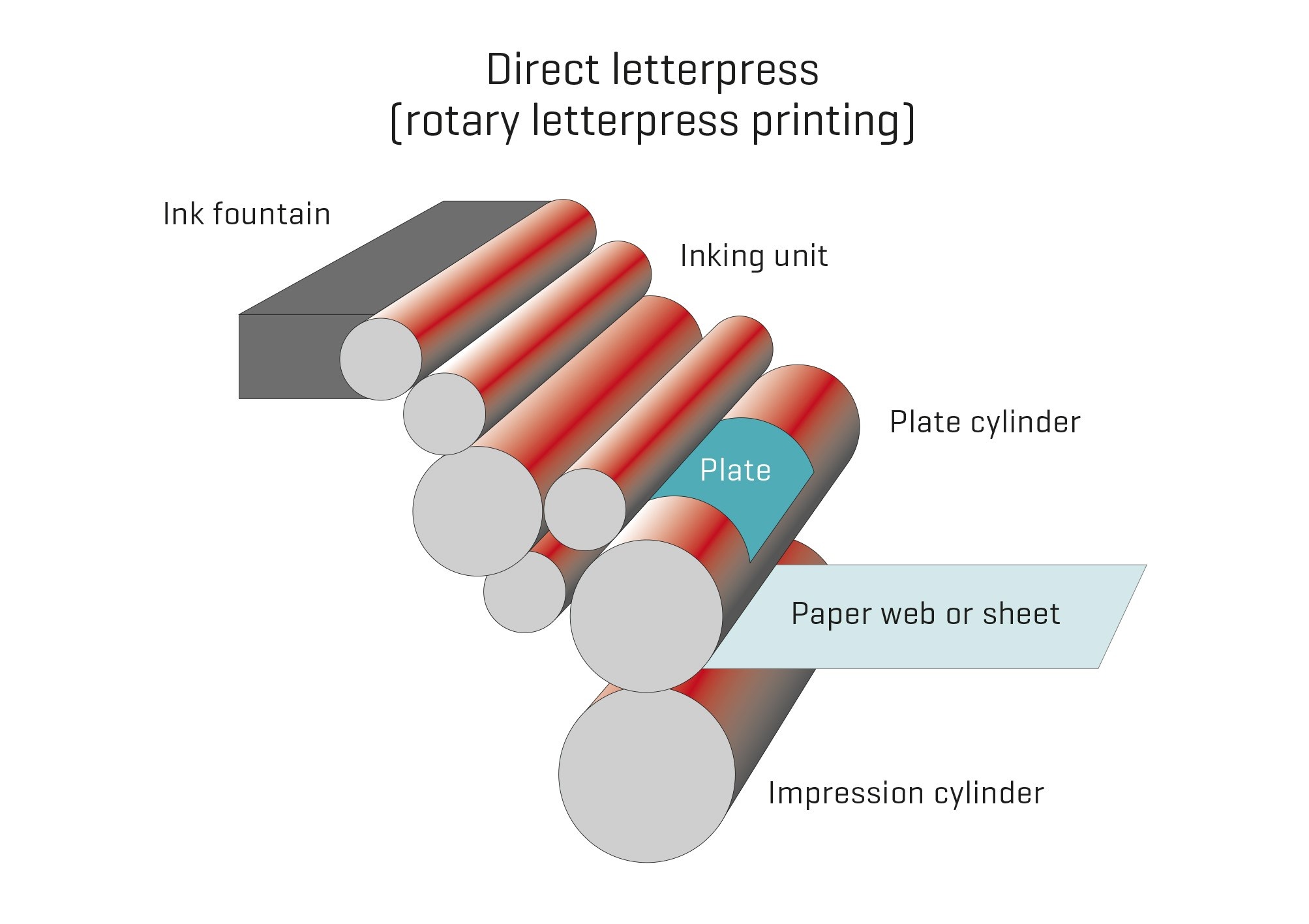

Letterpress print plates are inked over an ink roller set, controlled via ink-key settings. The image is transferred directly from the plate to the substrate using pressure.

In letterpress, graphics are built using dots - the smaller the dots, the lighter the color; the larger and closer the dots are, the darker the color.

Advantages of letterpress printing

Cost-efficiency of the letterpress printing process is a key factor in considering which printing press is more suitable for your business.

- Low tooling costs

- Fast change-overs

- High print quality

- Ideal for small jobs

Flexo printing: the process explained

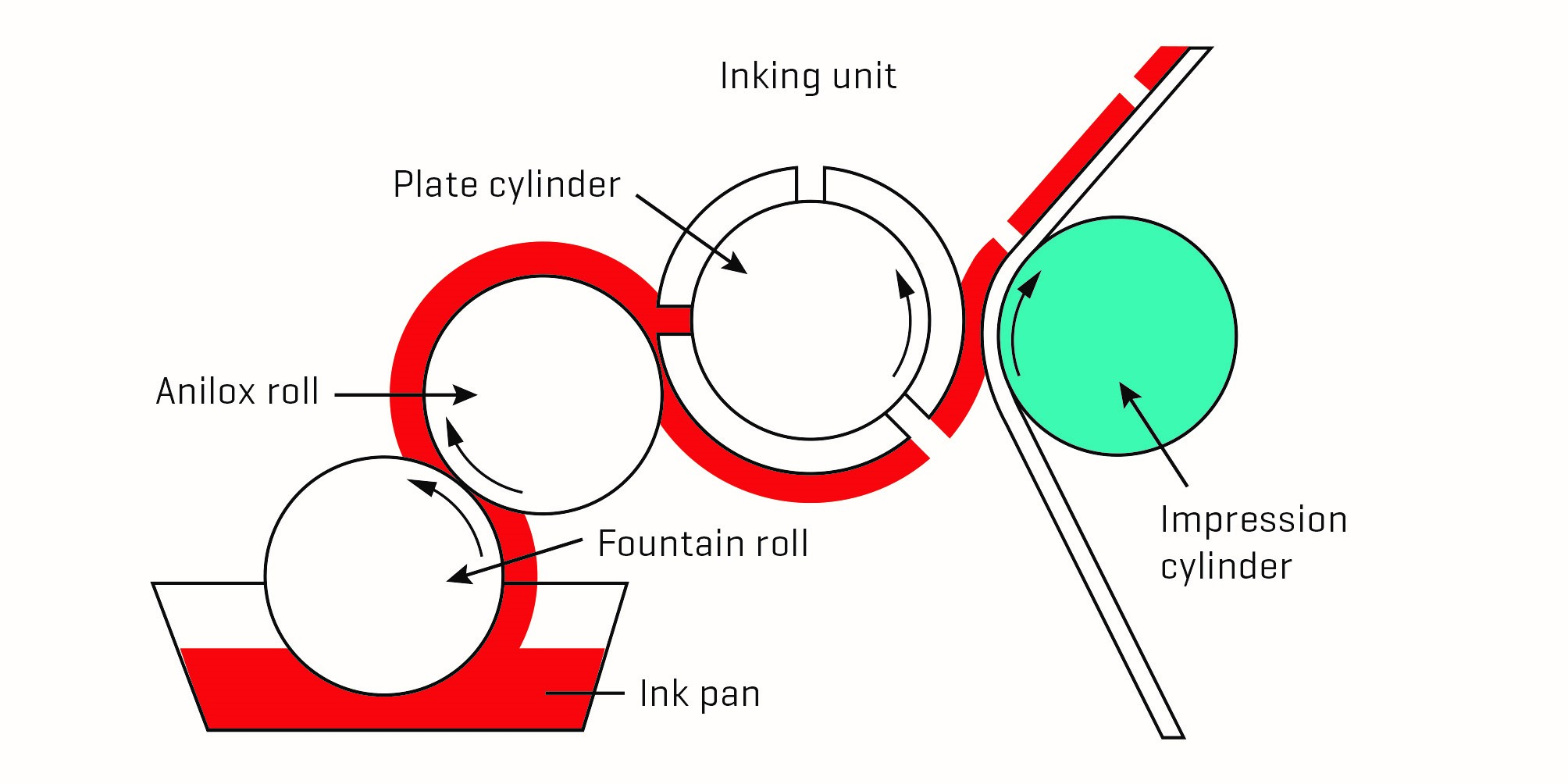

Flexography is a relief or raised image printing process using the same principle as letterpress. A flexible rubber or photopolymer plate is mounted onto the plate cylinder. The plate image is inked with a liquid ink which is transferred from the anilox roller, direct to the surface of the image area and then printed onto the substrate, using a very light controlled pressure (impression).

If you’d like to know more details of the flexo printing process, you may also like to read:

What is flexo printing? The printing technique explained

Advantages of flexo printing

- Short set-up times

- In-line finishing

- Minimum waste

- Guaranteed high-quality output.

- Less complex printing process for the operator

Whether letterpress or flexo is the better option for your business, completely depends on your type of business and customer orders. There are advantages for both technologies, and of course there are more options than just letterpress and flexo.

Would you like to know what to consider when choosing for flexo or letterpress technology? {{cta('263f41dd-8fa3-4429-9bd4-2d6bbf0c8ddf','justifyright')}}

Download our free whitepaper: ‘Letterpress versus flexo printing: how to choose the best option for your business’