A question we often hear when talking to printers is this: Should I buy the low-cost printing press or the higher-priced productive machine?

While each option has its pros and cons, a lower cost press is typically less automated and robust than a higher priced productive machine with more bells and whistles.

The advantages of a buying a low-cost press are:

- Low installment payments

- Low financial risk

Advantages of the more productive, but higher-priced press are:

- Shorter set-up time + more time to run more jobs per day = increased revenue

- Less cost of materials as set-up and registration is easier

- Less downtime for maintenance due to sturdier build of the press

- Opportunity to expand into new market segments and grow your business

The disadvantages of buying a lower cost press are:

The disadvantages of buying a lower cost press are:

- Longer set-up time per job. Therefore, less jobs are possible than a more automated press, resulting in less potential income.

- More material waste during job set-up

- More down-time for maintenance

Disadvantages of the higher-priced machine are:

- Higher payment installments

- Higher financial risk

So, what to buy?

From what we’ve seen, it all depends on the job portfolio. If you’re just starting a print business or simply do not have many jobs to run per day, the lower cost machine might make more sense for you.

However, if you already have a steady flow of jobs or expect additional growth, buying the productive, higher-priced printing press is a wise investment. You’ll have less waste, can run your press faster, and print more jobs per year.

You’ll simply earn more money in the long run with an initially higher-priced press – which will cover the extra installments. If you run a productive operation, the cost of the machine is just a small part of the overall cost of the finished label.

You may also like to read: What's beneath the iceberg: calculating your real printing press ROI

Competitive Price with High Productivity Machine from MPS

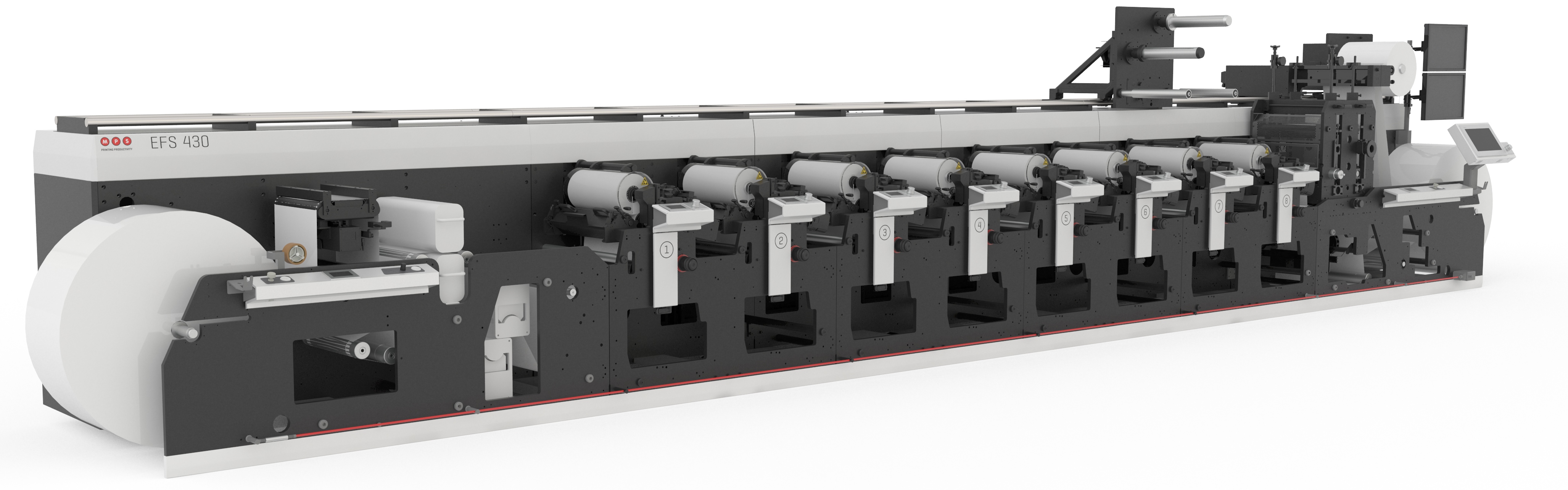

A press that is both competitively priced and highly productive, is the MPS EFS press. I’ll tell you some more about this highly automated press that may be the right solution for your business.

The EFS Automated Multi-Substrate press is a high-quality, highly automated multi-substrate flexo press especially designed for label production and flexible packaging printing on various substrates.

Providing the ultimate in flexibility, the EFS enables operators to maximize press performance, thanks to its ease of operation and reliability.

The high productivity EFS press provides an increased level of automation and higher print quality. It includes MPS innovations such as Job Memory, AutoTeach, iStop, and more.

Talk to me connectivity is another main feature of MPS presses. It allows for data exchange between Management Information Systems and MPS printing presses and generates performance reports (job and machine) for analysis.

Click here to download the EFS product brochure

Benefits of the MPS EFS Press

Why choose the EFS press?

With MPS patented technologies such as Crisp.Dot, E-sleeves, Job Memory, consistent excellent print quality for every new or repeat job is assured, even when run by different operators.

The high productivity and flexible converting also leads to lowest cost price per 1000 labels. Lower cost, higher profit!

Talk to me connectivity platform provides insight real time reports. Managers can improve the printing process by minimizing waste, optimizing machine capacity, comparing relevant jobs performances, and much more.

As said by an MPS customer: “The unique press design of the EFS made it easy for new operators to produce high-end work, where we repeatedly match colours using cartons printed with offset quality as standard.”

Of course there are more MPS presses available.

- The EFS is our most competitively-priced press, but when going for the maximum automation, the EFA is your printing press.

- When looking for both flexo and digital printing, the hybrid EF SYMJET press provides the best of both worlds.

- Going wider into packaging? Then choose the EXL-Packaging press for the highest speed!

- Rather use offset technology? We’ve got you covered with the EXL-Offset press.

Ready to know more about how MPS can help your business reach the next level? Contact MPS or your local representative now!

MPS. Operator Focused, Results Driven.