Two factors eventually determine the effectiveness of your flexo printing process: the operator and the printing press. You can make the press as intelligent and flawless as possible, but if it’s very complex to use for an operator, you still don’t get the desired result. Operator-focused printing innovations always lead to optimum press control.

To be able to achieve to lowest cost price per 1000 labels, it can be a smart move to start thinking about this. I’ll tell you all about these innovations in this blog.

Operator-friendliness: the key to a viable flexo printing process

As said, you can optimize your printing process and presses as much as you want, but when working with it is highly complex for operators you never accomplish the initiated result. They still have to perform too many or too complicated actions to get the required output.

If operators, for example, want to adjust the speed of the press, it slows down the process if they have to scroll through many menus and use a variety of buttons to complete this action.

Compare it to an iPhone: you don’t want to scroll or switch through various menus to get to the app you need. Or you don’t want different kind of buttons to complete separate actions. You want something as simple as one, clear user interface and control panel which makes operation almost automatic — just like the iPhone has.

Believe it or not, but the same goes for operators. Operator-friendliness means an easy-to-use press that enables rapid process changes and press feedback — so operators can take action quickly if something goes wrong.

5 operator-friendly printing innovations that help you to improve results

There are various printing innovations to improve operator-friendliness regarding both operation and ergonomics.

- An interface based on icons

Icons are a great way of representing ideas or messages into one succinct entity. When used correctly, we instantly recognize what they mean, without the need for any words. When you have an interface on your printing press based on icons, it simplifies navigation and enhances usability.

![]()

- Automatic job preparation

Automating the various processes, from pre-press to printing through to the final post-press stages, is a benefit to operators and business owners. Automation can be enabled by an interaction between printing presses and Management Information Systems (MIS).

The MIS is the link between all systems and software on the print shop floor. The MIS sends the job information via pre-press to the press and receives machine information back from the press. Data to be exchanged from the MIS to press includes the customer name, press run, color sequence, tooling, material type and thickness, printing plate code and planning (job queue). This data exchange means job preparation can be done automatically and operators can start a job immediately.

- Real-time press feedback

As said, the MIS can’t only send job information to the press, but it can also receive machine information. Such as printing speed, meters/yards printed (order status), waste produced (waste sheets), set-up and printing time.

This information enables real-time visualization of press settings to operators, so they can take immediate action if needed.

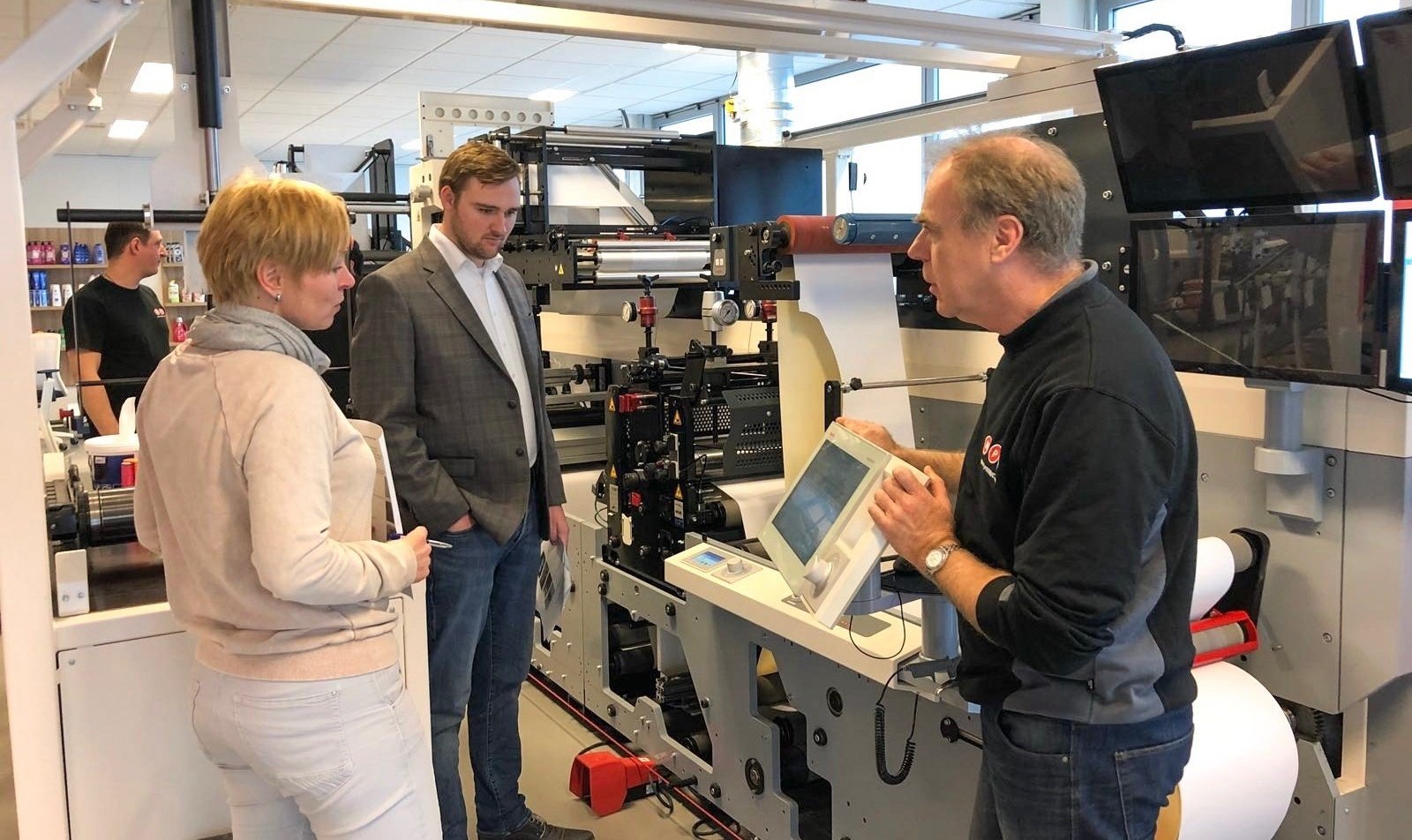

- Touchscreen & iControl on every single unit

This technology — which is simple, intuitive and stress-free to operate — enables the operator to choose and run individual functions via a small touchscreen and a rotary button, greatly simplifying machine control and operation, minimizing operator errors.

https://www.youtube.com/embed/DvqxYIAsufI- Ergonomic innovations

The innovations above are all operation innovations, but there are also ergonomic innovations. It isn’t optimal when a lot of physical work is required to set-up, run and finish jobs. These innovations make life on the print shop floor easier:

- Inserting and removing print sleeves on operation height.

- Ink slides to change inks and aniloxes effectively

- Excellent accessible web paths

Once an operator can optimize the use of a printing press — minimum waste, quick set-up and change-over time and minimum downtime — through a simple interface and control panel, it helps you to achieve the lowest cost price per 1000 labels.

Eventually, this is what you need to create a viable flexo printing process. If you want to discuss how you can optimize your printing process and how these innovations could help you — feel free to reach out to one of our specialists, they are happy to help.