As a project manager at MPS, I visit many different print factories all over the world and have the opportunity to take a peek into all kinds of print shops and to experience the local culture of how people and companies handle day-to-day care of their capital equipment.

Although there are differences between cultures and the way capital printing equipment is taken care of, the bottom line is the same: A machine needs maintenance!

No matter how modern, how much technology it contains, how skilled the staff is, or how professional the suppliers; presses need regular maintenance to keep them running optimally. On the internet I came across the following picture, showing that we will always be in need of good people who know, understand and practice what is needed!

This blog is the first in a series focused on press maintenance, based on my personal observations of existing narrow web flexo machines and the discussions I have with customers at all levels.

My passion for service and preventive maintenance

I guess my fascination for service and preventive maintenance began when I chose for a combination of good education and to see the world. Spending a few years in Her Majesty’s Navy had an impact not only on my personal life, but also on my professional life. Being on a vessel on top of a lot of water, and literally in the middle of nowhere, makes you realize you really want your equipment to be up and running 100% of the time. For the lifesaving equipment even 110% if that would be possible.

As an engineer, you were drilled to know that preventive or periodic maintenance was an absolute must. The schedules that were made and executed caused some equipment to get worn just because of the frequent and consequent preventive maintenance. All with the goal to have this equipment working the moment that you would actually need it.

Preventive maintenance in manufacturing

The production of a label printing facility will not go down immediately if the scheduled preventive maintenance is postponed by production pressure, as we sometimes see. At the same time, you expect your narrow web flexo press to be available to run production all the time to meet order demand.

With the market changing to:

- “Just in time” and decreasing printed product on stock

- Diversification in labels (more expensive and unique labels)

- Smaller runs and more design changes

- More expensive presses and converting options

- Higher utilization of equipment – 24 / 7 operation

- Higher investment & shorter and guaranteed ROI

…printers do not just want, but actually need their presses to be reliable and available to run production all the time to make sure the revenue will be sufficient to keep the company healthy and profitable.

No press down

But…preventative maintenance needs priority in your production schedule as well! It may seem annoying, especially with so much order activity going on, but a completely down press requiring emergency repairs is the last thing you need when trying to fulfill urgent orders!

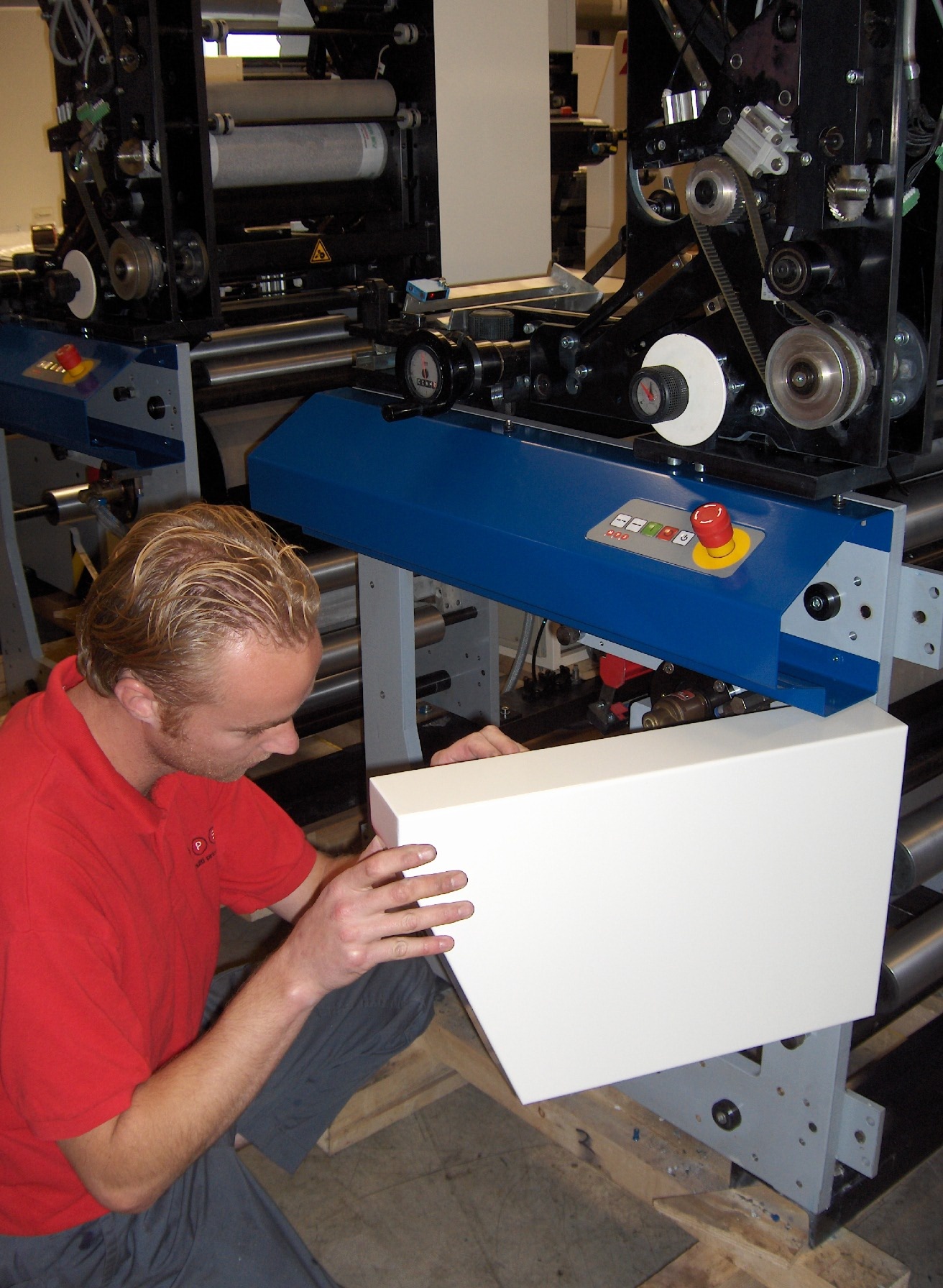

Preventative maintenance avoids potential failure by regular check-ups. It provides an opportunity to clean and lubricate the press, fine-tune all the hardware components, replace necessary parts, and ensure software is up-to-date.

This blog is part of a series of blogs that I’m writing about my experiences as a Project Manager. In the upcoming blogs, I will discuss the following topics:

- Do it yourself, or outsource?

- Implementing a new press in an existing printshop

- The costs of preventive maintenance

Would you like to know more about the MPS service organization and how preventative maintenance can help you? Download the infographic about MPS service here!