In this fifth edition of my blog series on preventative maintenance, I look at the evolvement of printing technology and who is most capable in maintaining your press investment with today’s production environment.

Shift in technology and maintenance

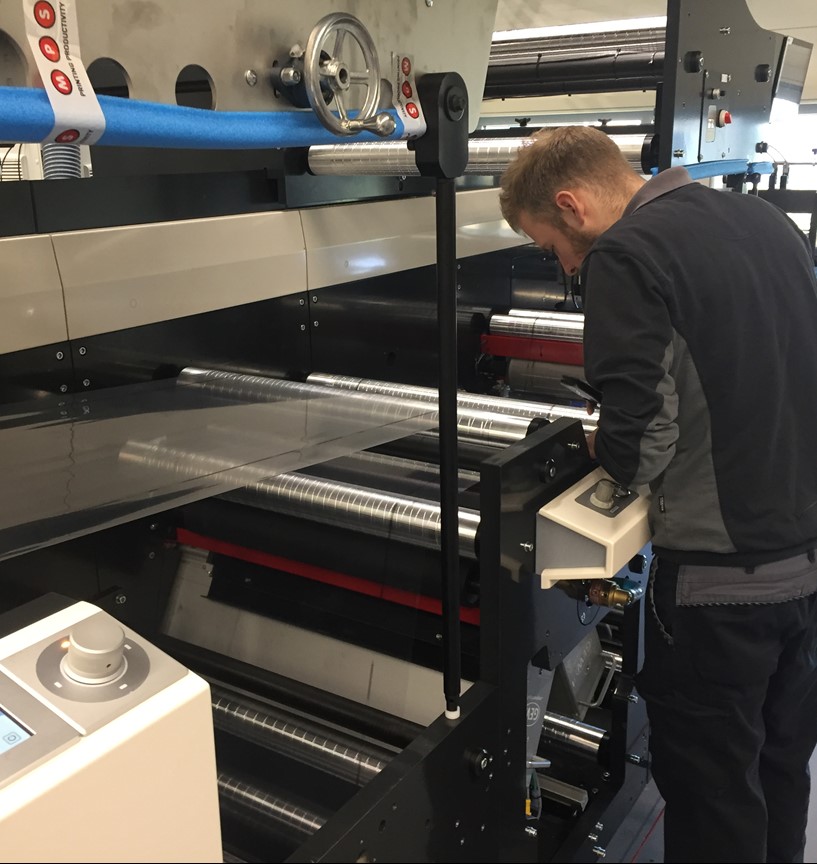

In recent past, maintenance on a flexo printing press could be done, and well, by generally skilled technical staff.

Back then, a press only had a few mechanical options so a big part of maintenance was good old-fashioned lubrication, replacing wear & tear parts and a few adjustments.

Printers either had a local maintenance person on-site or hired the city mechanical engineer if needed. Parts breaking down and causing machine down time were mostly mechanical parts that could either be repaired or copied by the ‘local black smith’.

Modern presses of today require a different type of maintenance

Since brand owners didn’t change designs as often as nowadays, larger volumes of identical labels were ordered and press down-time was not as critical.

Keeping finished product in stock made it easier for printers to deal with a machine coming to a standstill. Surely, every minute not running production also in the ‘old days’ was lost money, however with current low volumes and high turnaround times of labels the critical point has shifted - resulting in the need for constant uptime of the machine.

With the introduction of servo-drive technology and other state-of-the-art control technology and options, printing presses have evolved into a high-tech machine developed by new disciplines like control & software engineers who have no relationship to printing.

With the introduction of servo-drive technology and other state-of-the-art control technology and options, printing presses have evolved into a high-tech machine developed by new disciplines like control & software engineers who have no relationship to printing.

These fresh minds and new modern technology created machines which were also able to print. In general, one can say the label industry had difficulties keeping up with the latest technologies that press manufacturers and new emerging suppliers introduced.

Hiring within vs. outsourcing technical expertise

For printers, modern technologies resulted in the need to hire highly-skilled maintenance engineers inside the factory.

Most larger printers can afford the luxury to do so, whereas the smaller printers struggle. The use of remote diagnostics and service possibilities makes a big difference compared to the old days. Printer & supplier are literally working together to keep the press up and running. At the same time, you also see in our industry the tendency to keep doing what you’re good at and outsource the secondary processes when possible.

Outsourcing machine maintenance is a good example where cost certainly pays off in benefits.

A maintenance engineer’s skillset needs to be broad

In the old days, it was quite easy and wise to use an outsider to perform necessary maintenance. Whether corrective or preventive, it becomes more challenging with modern-day presses.

Knowledge about machine control systems and software extends beyond standard PLC knowledge. Although a major part of maintenance on modern day presses continues being the regular cleaning & lubrication, a periodic check by a specialized engineer from the press supplier is becoming more vital.

Press manufacturers, driven by what the market demands, are making their top-line machines more and more sophisticated by using the latest state-of-the-art electronics and software, most of which is customized.

Modern day electronics can be supplied around the globe and remote diagnostic possibilities makes customized software accessible 24x7, eliminating much of the need for the local maintenance man.

The press supplier (service) engineer

Changing team expertise from the perspective of the label printer also applies to the press manufacturer.

They also need to diversify their service team, and most of all communicate to printers that the days of ‘1-engineer solves all’ are over. Good overall service engineers know a bit about all parts of the machine and the applications that run on it.

But when it comes to corrective maintenance visits, specialized skills are more often required. Such as, an engineer more specialized on the control side of the machine (whether AT the machine or remotely connected to the manufacturer’s factory), a mechanical engineer and a printer, or application engineer.

In executing preventive maintenance, the overall dedicated service engineer from the press supplier is the best option.

They know all parts of the press better then anyone, is trained on the specifics of your machine and – very important - has a direct line to specialists at headquarters. With this knowledge, they can make a good and fair assessment of the situation and provide valuable advice of steps to take.

Together with the evolution of printing presses in the narrow web label market, those maintaining these modern state-of-the-art machines also have evolved from technicians to specialized Service Champions!

Long-term stability with preventative maintenance

I’m not saying you have to go out and purchase the most expensive and extensive service-level agreement (SLA) available. My suggestion and challenge to you is to start thinking and discussing preventive maintenance.

Talk to your team in operations and technical support. Also ask your financial experts to make a calculation of the parameters related to production equipment that are important for you and your business.

In the opinion of some, the reversed cost method called ‘run till it breaks’ is still quite popular. If you get away with that, and still run a profitable business, then stick to it.

On the other hand, knowing operational costs in advance together with a performance or uptime guarantee would make your business more profitable and certainly more stable in the long run.

Get in touch

Please feel free to share any thoughts you have on this topic above or preventative maintenance in general. I look forward to your replies and suggestions!

In my next and final blog, I’ll discuss the future of modern flexo press maintenance. Will it remain preventive or are we going towards predictive?

For service-related assistance including spare parts and SLA’s contact our service team at: service@mps4u.com

Until then, you may be interested in reading my other blogs in this preventative maintenance series:

Part 1: A machine needs maintenance!

Part 2: Keep your flexo press and operator at their best