Many different parameters influence the cost price per 1000 labels:

- the press itself;

- pre-press work;

- post-press work;

- the operators.

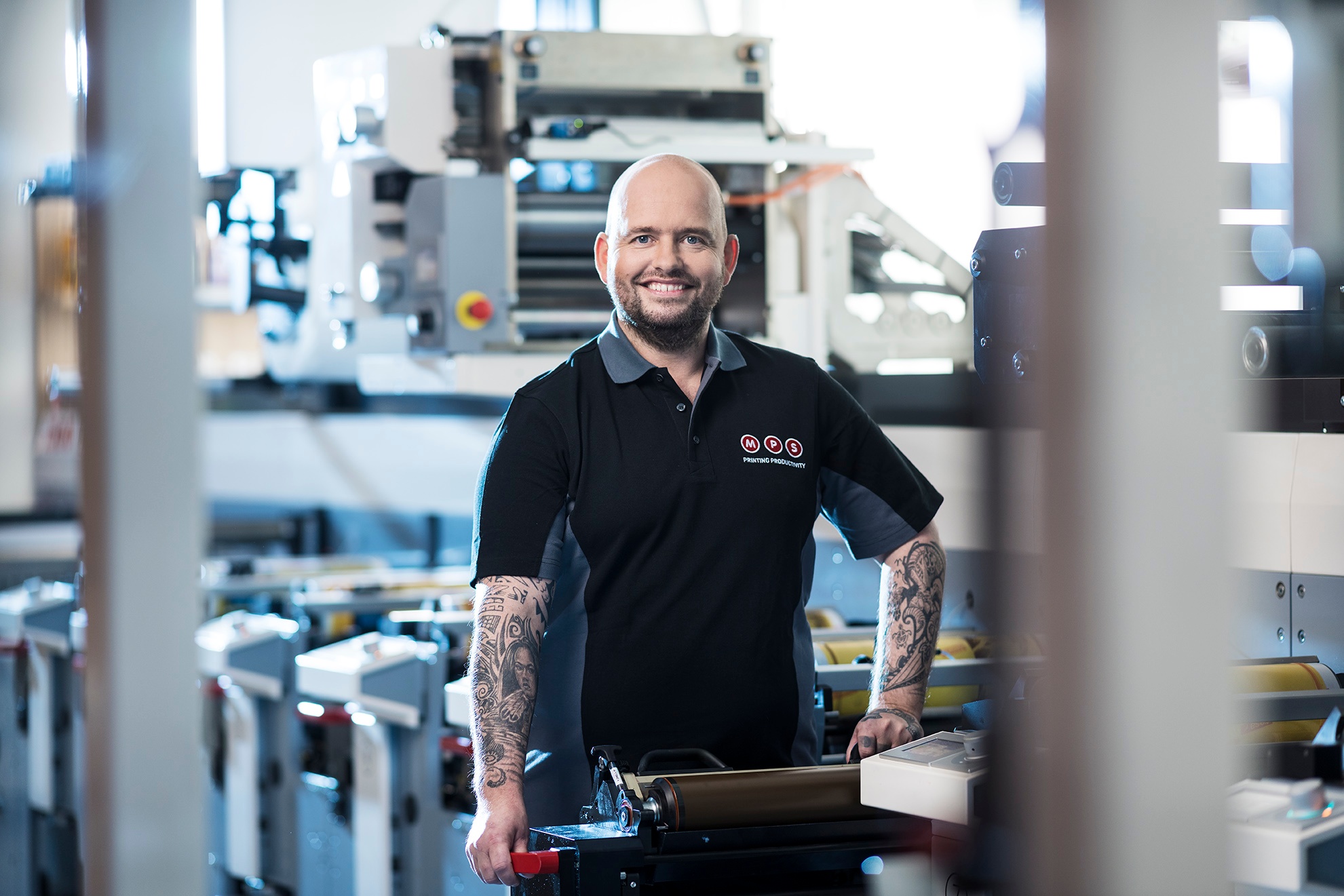

Yet, studies have proven that a motivated operator is the most important parameter in the printing process. Therefore, operators are the biggest asset or the biggest dissonant in achieving the lowest cost price with consistent, high-quality output. In this blog, I will tell you all about the ‘why’, and how to increase your operator’s motivation with simple printing press features.

The output defines the press operators’ motivation

A printing press operator has a sole goal: high productivity and quality output. If there are many factors that negatively affect this output, like complex press control or less predictable press behavior, you can imagine that his motivation decreases. Printing press operators simply want a predictable printing process so that high-quality output can be ensured. In other words: they need a companion-press to assist them in their daily work and routine.

4 printing press features that improve the motivation of printing press operators

With this in mind, it can be a smart move to choose printing presses that are predictable and user-friendly. As a result, operators know exactly what happens if they push button A, B, or C or change setting X, Y, or Z.

I’ll give you some examples:

Press control with a rotor-click

A printing press contains various controls for different purposes, including the final position of print sleeves and aniloxes. When these controls have a rotor-click to it, operators feel what they are doing without taking their eyes off the substrate. They know exactly what they are doing and will know exactly what happens by how many ‘clicks’ left or right it has been turned, minimizing error.

Aniloxes with handles

It sounds incredibly simple and it’s only a very small part of the entire printing process, but aniloxes with handles make life on the print shop floor easier for operators. Dirty hands slow down set-ups and changeovers. Anilox rollers fitted with handles for transport, positioning or removal speed up this process.

Slide-out ink drawer

A simple feature that makes the operator’s life a lot easier and cleaner, is the option of slide-out ink drawers. Instead of bending into the press to change the inking elements, the operator can easily slide out the ink drawer and change the inking elements for another color, anilox or doctorblade settings. No more need for dirty hands!

Objective press feedback

Printing press control becomes even simpler with a fully automated press. Every setting is visible through numbers so operators exactly know what the press set-up is. Therefore, incorrect settings become a matter of the past, resulting in the desired output. Operators are assured of objective printing press feedback.

Efficient and proven technology is obviously important for printing presses to deliver in terms of quality and productivity. But the true difference is made by the people behind the controls. If their presses are reliable and easy to use, they will enjoy their work more and, as a result, do a better job.

But user-friendly printing press have another plus side. In today’s printing market, it is becoming harder and harder to find and keep skilled operators. By simplifying the printing process, it is easier to find and train staff to operate the press.

There’s more than just user-friendly and predictable printing presses

Providing user-friendly and predictable printing presses are one thing you can do to increase operators’ motivation. But there’s more:

- Preventive maintenance: Frequent maintenance increases productivity and therefore increases motivation.

- Integrate presses in business processes, including a link with MIS: This integration means sending job runs to your presses that can be centrally managed. Therefore, every single job — including all the required press-setting data — is delivered to the presses, and operators only need to do fine tuning before running the job. The quality of the output is ensured because of reliable data entry, including objective press-setting feedback (by numbers).

Yet, user-friendly and predictable printing presses are essential if you want to increase operators’ motivation. It’s the one thing they have to work with every single day. The drive of operators doesn’t just influence the cost price, but (indirectly) also affects the viability of your printing process.

Many elements within your printing process exist that determine its viability. If you would like to receive an indication on this viability, we have a useful tool that helps.

The only thing you need to do is answer 9 short questions. Each question involves a different topic that affects the viability of your printing process. It helps you find out to what extent you should consider implementing process optimisations, and in what areas.

{{cta('fd4ce9db-466d-4995-8a85-d1284b3b741d')}}