It’s the goal of every printing company in the label industry: the lowest cost per 1000 labels. Especially in the current market, where prices are under pressure, and job sizes get smaller and smaller. But this objective depends on many different factors, of which reducing downtime and printing waste are the most crucial ones.

And that’s your responsibility as a production leader. It’s your job to create a stable and predictive label printing process. To achieve this, you need to continuously optimise it. But where do you start? Real-time insights are extremely valuable to focus on those parts of your process where there’s room for improvement. I’ll tell you more about it in this blog, so keep on reading!

The meaning of real-time insights in the label printing industry

You can have a stable and predictive printing process, but there’s a fair chance that you still don’t know what the exact costs — to the decimal point — of a job run are. And if you want to be able to offer your customers the lowest costs, you need to know what the cost price of a label is. Preferably as soon as possible.

And that’s where real-time insights come into play.

Before I tell you more about the advantages, I’ll explain to you what real-time insights mean in the context of a printing process. It is a broad concept that speaks for itself, but it can be applied in different ways with various techniques.

In the label printing industry, real-time insights are relatively new. In short, it’s an extra option you can add to your printing presses on the condition that they are equipped for this and support it.

There are three types of data that can enable real-time insights:

- Print settings for initial and repeat jobs (preferably automated by servo control to reduce set-up waste)

- The press’ main computer settings: calculated speed, the amount of printing waste, etc.

- The data from cameras for quality control

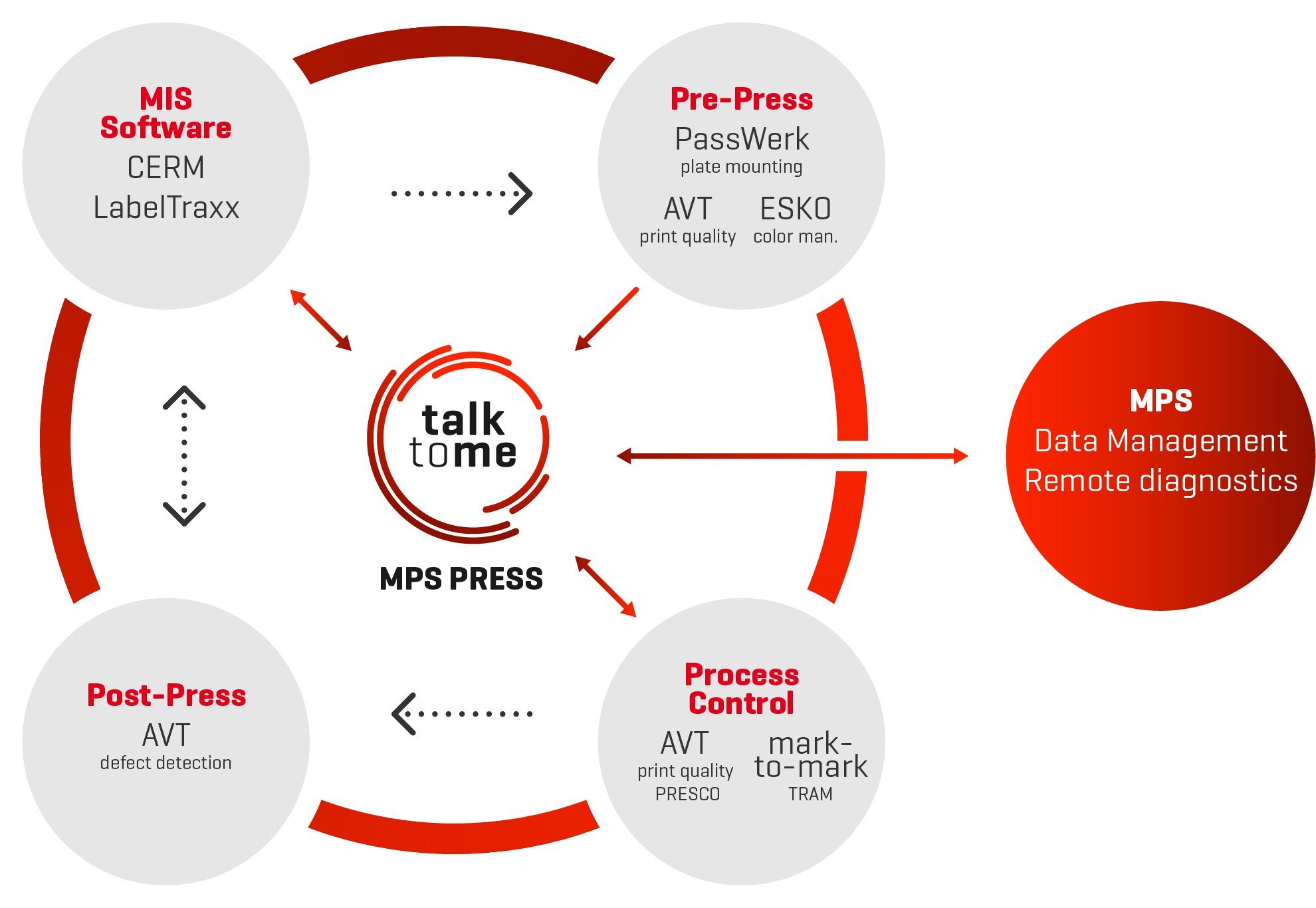

A real modern automated printing press contains this data. But to get this data real-time, you need an integrated unit that shares the available data directly to a central system.

We call this the connectivity platform. This platform communicates all the job-related data directly with your Management Information System (MIS). And all the press-related info is directly uploaded to a mobile device through a corresponding app.

This provides you with all the real-time insights you need to have — from the amount of printing waste to the quality of an end product — on your computer or phone.

Knowing this, you can imagine that this helps to determine what the exact cost price of a single printed label is, right at the end of every job run.

The added value of real-time insights into your label printing process

This doesn’t just help you to gain direct insight into the cost price per label, it also tells you:

- Whether the planned schedule is going to be met

- If a job is running on the calculated speed

- The waste figures

- The exact status of all the jobs currently running

- Why a press has stopped running and how you can respond immediately and accordingly

These are just a handful of examples of what kind of information you can derive from real-time insights.

Real-time insights also have their effect on production preparation. Because of the integration of a connectivity platform, all the data is available in your Management Information System. But your MIS can also communicate with the presses. This means sending job runs to your presses can be centrally managed and you no longer have to divide the runs between the printing presses yourself. As a result, you can fully focus on the process, and you no longer have to deal with peripheral issues.

Real-time insights help you to get more grip on the entire printing process and implement more targeted process improvements. And that leads to cost reduction, because in an optimised printing process there’s less wastage of time, labour, and equipment. You can run more jobs with the same resources.

What ‘next steps’ can you take?

Maybe you’re thinking: ‘this is something I should consider’. If so, then what are the next steps you can take?

Because real-time insights are relatively new in this industry, a wide range of products is not yet available. Therefore, you would most likely look at acquiring a new printing press with the described extension. This investment is worth considering if cost price reduction is of high importance within your organisation. Because once you have real-time insights, you can truly optimise your printing process and significantly reduce the cost per label, ensuring a more competitive position in the market.

Also keep in mind that automation is increasingly becoming a hot topic, not just in the printing industry. Be aware that you’ll be confronted with this more and more in the upcoming years. Are you prepared for that? Is your printing process future-proof?

Feel free to further discuss what real-time insights and automation can do for your company by speaking with one of our printing specialists. You can contact them here.

There are more ways to optimise your printing process

You are well aware that a streamlined printing process is pivotal to produce high-quality end products at the lowest costs. Gaining real-time insights into your printing process isn’t the only method you can consider to optimise your printing process.

But do you have an idea how viable your printing process actually is in the long term? In other words: how future-proof it is? If you’d like to receive a global indication of that viability, we have a useful tool that helps.

The only thing you have to do is answer 9 short questions. Each question involves a different topic that affects the viability of your printing process. It helps you find out to what extent you should consider implementing process optimisations, and in what areas.

{{cta('fd4ce9db-466d-4995-8a85-d1284b3b741d')}}