As I said in my previous blog, the converting in your hybrid press can be done in-line and saves costs in your printing process. When we focus on die-cutting: MPS’ integrated die-cut unit has the capability to run in both full- and semi-rotary mode.

What is semi-rotary die and what are the advantages? I’ll explain in this blog.

Semi-rotary

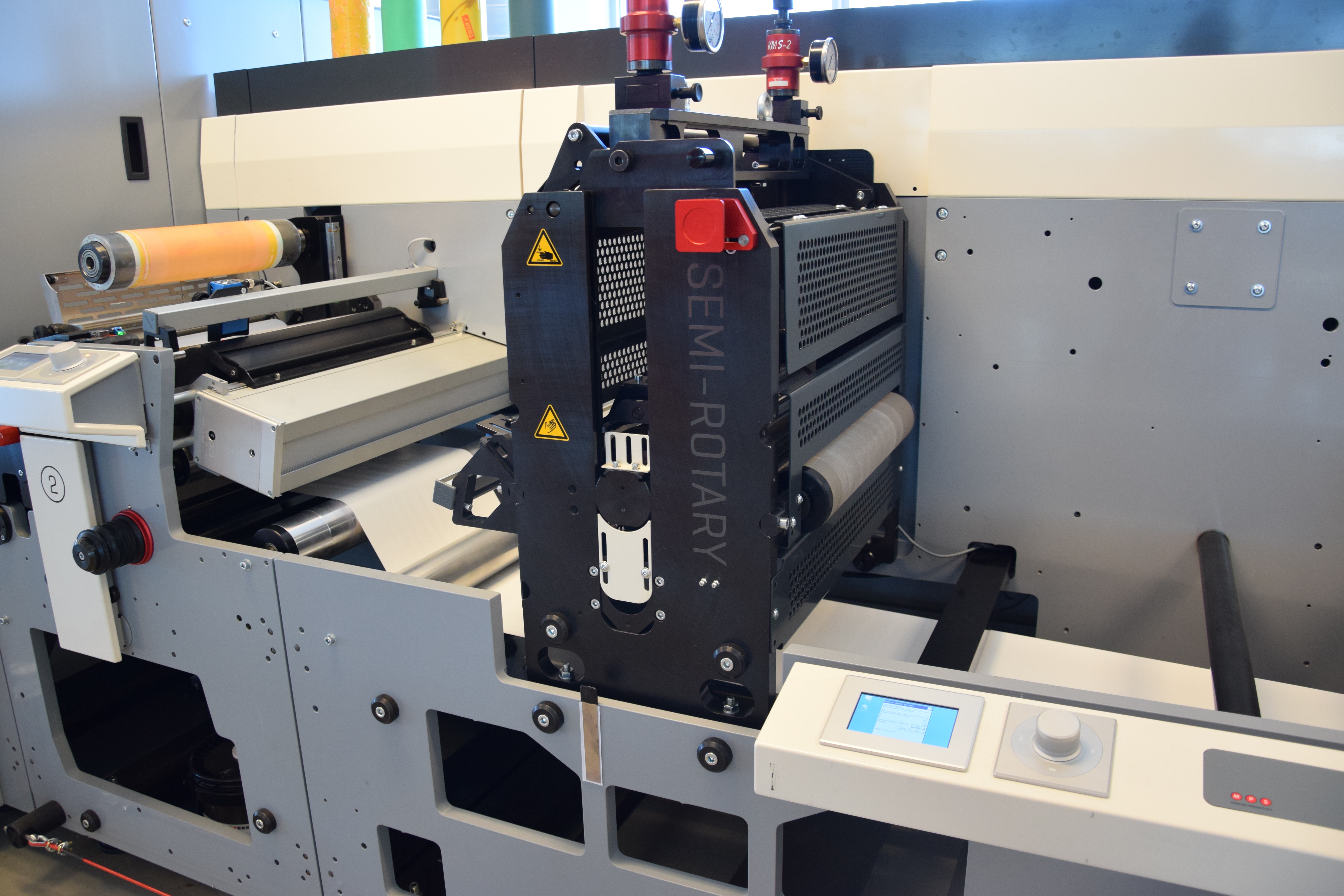

In full-rotary mode it performs as a normal rotary die. Run in semi-rotary mode, the die has only one fixed magnetic die cylinder in one (maximum) repeat size where you can mount flexible dies of any repeat size up to the repeat of the die cylinder itself.

The die-cut plate is covering a part of the cylinder. The web is servo controlled and corresponds to the die-cut plate, it accelerates or idles to perfectly fit die plate size and die cylinder size up to full production speed.

The unit is, like all other converting modules in the EF SYMJET, integrated into the system and controlled by the main control panel. MPS has developed a quick change hoist and integrated lay-off table for very fast tool changing when changing in between semi-rotary and full-rotary mode.

Semi-rotary

Semi-rotary

The advantages of semi-rotary die-cutting

Saving on the tooling

Depending on the size of the label and the length of the run, you can decide how to manage your production costs. You can opt for a small die-plate or a large one. The smaller the plate will be more beneficial for smaller runs.

Besides that, with the semi-rotary die you only need one magnetic cylinder instead of one for every repeat size!

Less down time for setting-up die cutting

Another advantage is that the set-up time is shorter, because you don’t need to change the die cylinders on every different (repeat) job, it’s just the plate with an integrated plate changing tool. This means it takes less time to change-over to a new job with a different shaped label. Also, with the use of the quick change hoist system, a fast cylinder change is possible.

High speeds

Don’t worry that you need to compromise the speed with an semi-rotary die: the maximum speed of this die-cut unit is corresponding to the speed of the digital print engine, so it’s not reducing the speed of your hybrid printing press.

The semi-rotary die is one of many valuable innovations in cost and time savings in hybrid printing. Want to learn more about hybrid printing and the features of ourEF SYMJET? Download our free whitepaper here.

{{cta('75f31875-db1c-44ac-abb6-add382e30948','justifycenter')}}