Historically there are primarily 3 types of tubes used for packing of various liquids, pastes & creams for Oral care, Pharma , Beauty/Cosmetics , Food products & Industrial products (like paints & adhesives).

- Aluminum tubes: still used for aggressive industrial products (adhesives, solvent based paints etc), barrier crucial pharma products & beauty products (like hair colors).

- Seamless tubes : Here each tube is individually extruded & printed in the round. They have the advantage of higher possibility of decorative / variation of Caps. But have low barrier properties, hence thicker & with a much higher cost of production. Primarily used for beauty/ cosmetic and some food products. Specially for smaller quantities & low barrier compliant products.

- Laminated tubes: these have two sub categories:

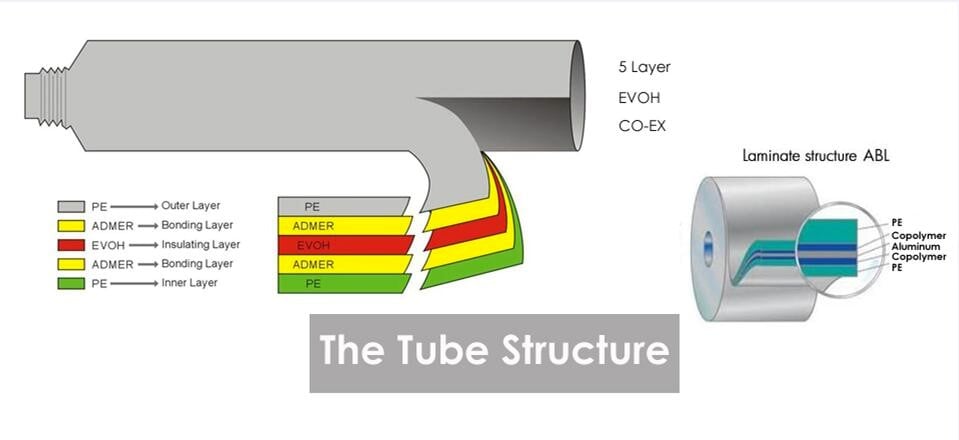

I) ABL (which contains a central Alufoil barrier layer). Alu layer is laminated with the co-extruded polymer layers. Hence it is more stable due to the Alu layer, but gauge variation can be observed.

ii) PBL (This has an EVOH polymer central layer for barrier properties) All layers are polymer & co – extruded. Since it is an all polymer construction, it is more susceptible to heat and tension. But the PRIME advantage is that it can be transparent, which is the demand for Cosmetic & Beauty products, where the packaged product itself needs be seen!

Printing lami tube material in flexo

Where as before, 99% of the lami tubes were printed in letterpress because it allowed easier register on the gauge variation material , as all colors are printed around one CI cylinder. But long job change-over time, color change, print quality & much lower speeds of production are the limiting factors. Also most of these presses cannot easily convert PBL material.

Due to demands of decoration on tubes increasing & more prevalant use of PBL (transparent) tube material

Nowadays, flexo is the preferred process for printing on lamitubes. Mainly due to :

- higher print quality,

- quick job changeovers,

- ease of use , for value adding decorations (like cold foil & rotary screen)

- ability to easily convert PBL material.

- higher production speeds

Many converters are now switching to flexo printing because of the print quality & decoration demands from end users.

Challenges in lamitube printing - 3 things to take into account

The printing of laminated tubes, or; lami tubes, can be challenging in in-line, modular flexo presses. Lamitube material has the highest share for toothpaste, food, pharma and cosmetics. The tube material is made of multilayer plastic, and sealed by RF along the seam.

To print on lami tube material, there are certain things to take into account.

- The layers in lami tube material behave differently. Pre- stretching: Lamitube produced in wider web, when slit or stored for longer periods can develop some wave like distortion on the edges of the slit rolls , more so in ABL material, due to differential tensions between the 5 laminated/ co extruded layers, specially as Alu layer is the most stable/ inert . This ensures a perfect flat material is fed into the press for printing. PBL material is more sensitive to heat,

- Control the web tension to avoid stretching : Lami tube material tends to stretch during the printing process. In order to avoid the material and the image to stretch during printing, you have to make sure the web tension is lowest possible but enough to have perfect control on the web. The right web tension is essential to print in register. The web transport in the MPS EF press makes it possible to transport the web through the press without stretching, but also without the need for a pre-stretcher in front of the press or any other pre-conditioning of the substrate, if it is distortion free.

You may also like to read: The importance of web tension on a printing press - Lami tube is heat sensitive : Lami tube material is a very heat-sensitive material. This, you have to take into account both in your web transport (where you need good cooling) but also in your drying. Drying lami tube material is a challenge, which is caused due to differential reaction of different layers to heat from UVlamps. UV curing works very well in combination with chill drums, to keep the web at a low temperature. As lami tube material is co-extruded from different layers of plastic, sometimes with a plastic or aluminum barrier, you have to know that these layers have a different density, tension and thickness. When the material goes through the printing press, all the layers (mostly 5) have to stretch in the same way in order to prevent visible differentiations in material thickness.

Lami tube in the Indian printing market

In India, lami tube is a big part of the printing market. Some Indian companies have a substantial share of the world tube market. There are companies that produce the tube material and also print it, but there are also suppliers that only produce the substrate. Some print the material & send the web abroad to their tubing facilities/ susidiarie companies.

Whether printed in letterpress or flexo, lami tube is still a challenging substrate to print!

Hopefully, this blog will give the reader an insight about printing on lami tube material.{{cta('cdc2ffa5-18f5-4ac9-b50e-f80e168337b4','justifyright')}}

Do you have a question about lami tube printing or another subject? Please don’t hesitate to contact the MPS specialists! Click on the ‘speak to a specialist’ button to get in touch, and we’ll be happy to help you.

Vijay Pareek, Director of Genius Flexo Machinery, is the local representative of MPS in India, Sri Lanka and Bangladesh.