As you could see in FAQ Friday #18, stable web tension is important – for consistent high print quality without adjustments by the operator, and minimum waste of material and time for the best results.

When incorrect web tension is applied to the material, this has (negative) influence to;

- Register out of tolerance

- Whilst laminating, the material can curl up when you stretch one material more than the other

- The material can wrinkle especially at the rewinder, when the tension is not correct

The effect of these undesirable results is wasted material and wasted time: the press needs to be adjusted, and as a result the press will be occupied longer. Finally the wasted material needs to be collected and destroyed. To avoid these problems, MPS improved web tension of its presses.

https://www.youtube.com/embed/olnm1TjuNVA?start=14

Automatic web tension control

The MPS presses automatically control the web tension throughout the entire machine. The web transportation and printing technologies are separated completely from each other. In this way the print units and other converting modules have no influence on the overall web tension.

The result; a perfect register and predictable set up waste for all different materials, achievable by all operators!

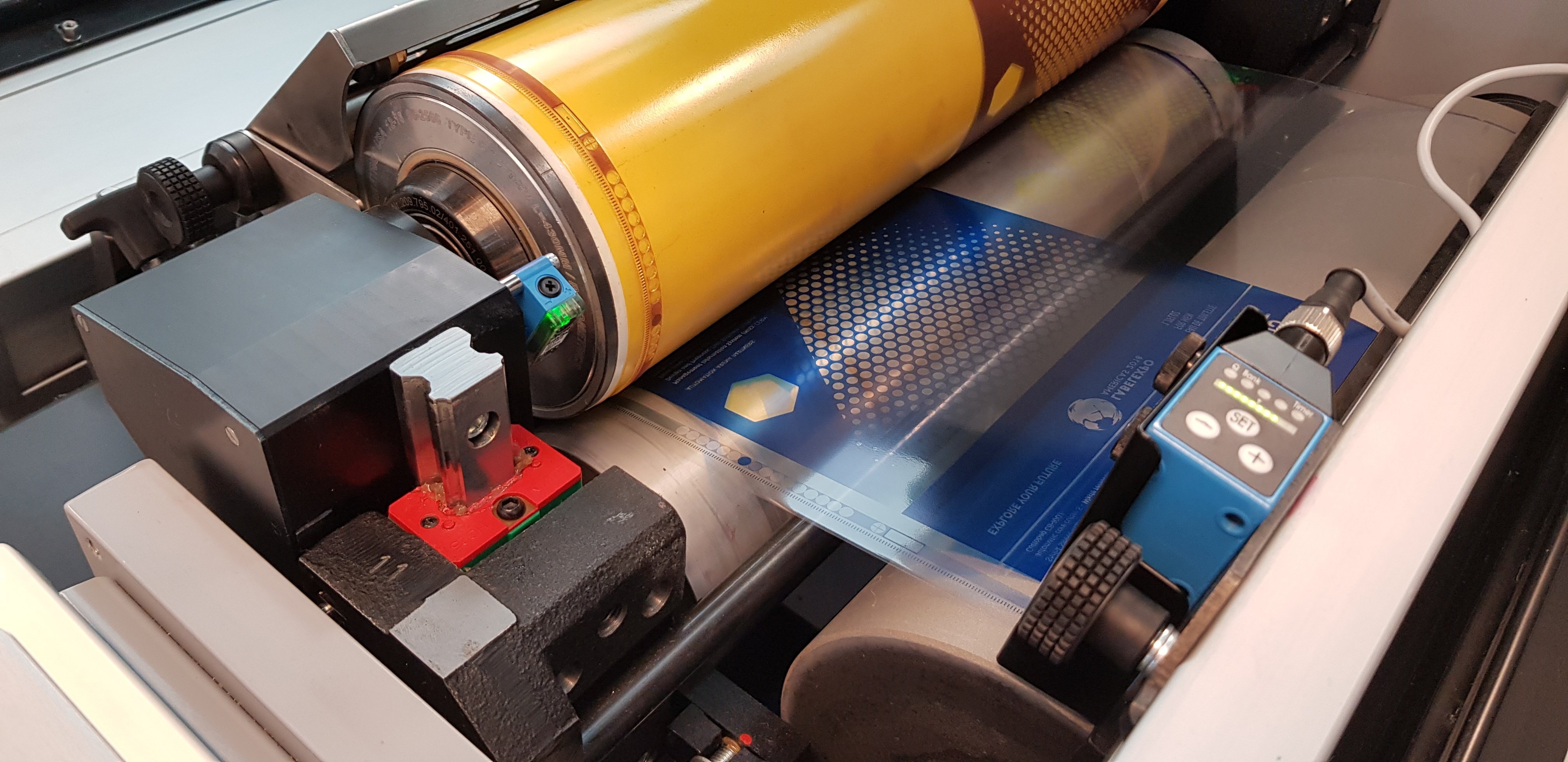

Free running impression cylinders

To realize this tension free print-technology, the printing stations have free running impression cylinders. The web is transported through the machine by the driven chill drum rollers. The chill drums in the MPS technology have a premium task of web transport, next to chilling the web after UV drying.

Web tension adjusting by the operator

The operator sets the desired web tension in the main control panel, depending on substrate and / or application. This web tension can be stored in job memory for each material or job. With every new job, tension can be loaded from memory in order to achieve the highest productivity possible.

After loading up the tension, the press stabilizes and controls it automatically. With MPS’ press improvements, the web tension stays more consistent and requires less adjusting effort from the operator, resulting in a low and predictable cost price per 1000 labels.

Take your printing process to a next level

Want to know more about web tension or other innovations of MPS? Or want to discuss how you can bring your printing process to the next level? Leave your question here and one of our specialists will contact you!

{{cta('cdc2ffa5-18f5-4ac9-b50e-f80e168337b4')}}