It’s a trend – many label printers are making the transition from conventional to digital printing to keep up with market demand. Digital printing has some strong benefits over flexographic printing, however, flexo should not be neglected.

Here’s why digital printing alone is not enough, and how you can combine the best of conventional and digital printing - all in one press.

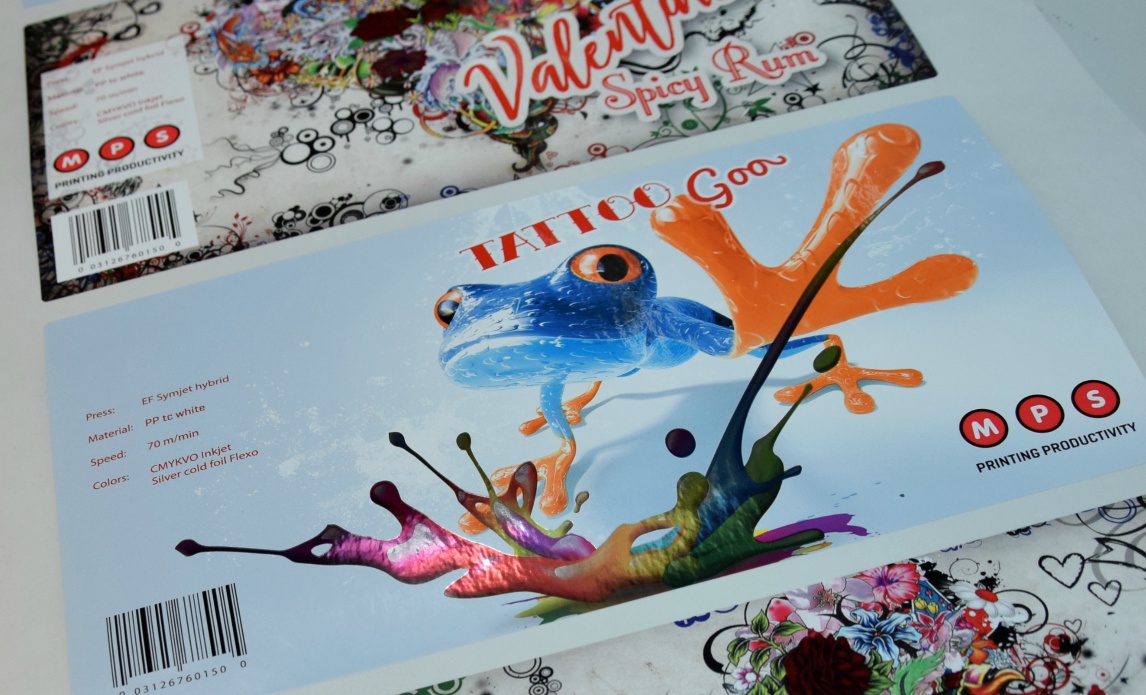

Eye-catching effects

As I mentioned, digital printing has many benefits compared to conventional printing, such as faster turnaround times, personalization, lower costs for short run print jobs and great flexibility.

But can your digital press print the following highly popular applications and special effects?

- Cold foil

- Delam / relam

- Metallic shades

- Hot stamping

- Screen printing

- Laminating

- Varnish

- PMS colours

A digital press prints high quality labels, but they’re just images - simple labels. If your customers need special effects to really draw attention on the shelf, like a shiny gold or sparkling silver layer, you will need a flexo unit.

In-line finishing

I bet you’re thinking: “I could print on my digital press and add that varnish or die-cut them off-line.”

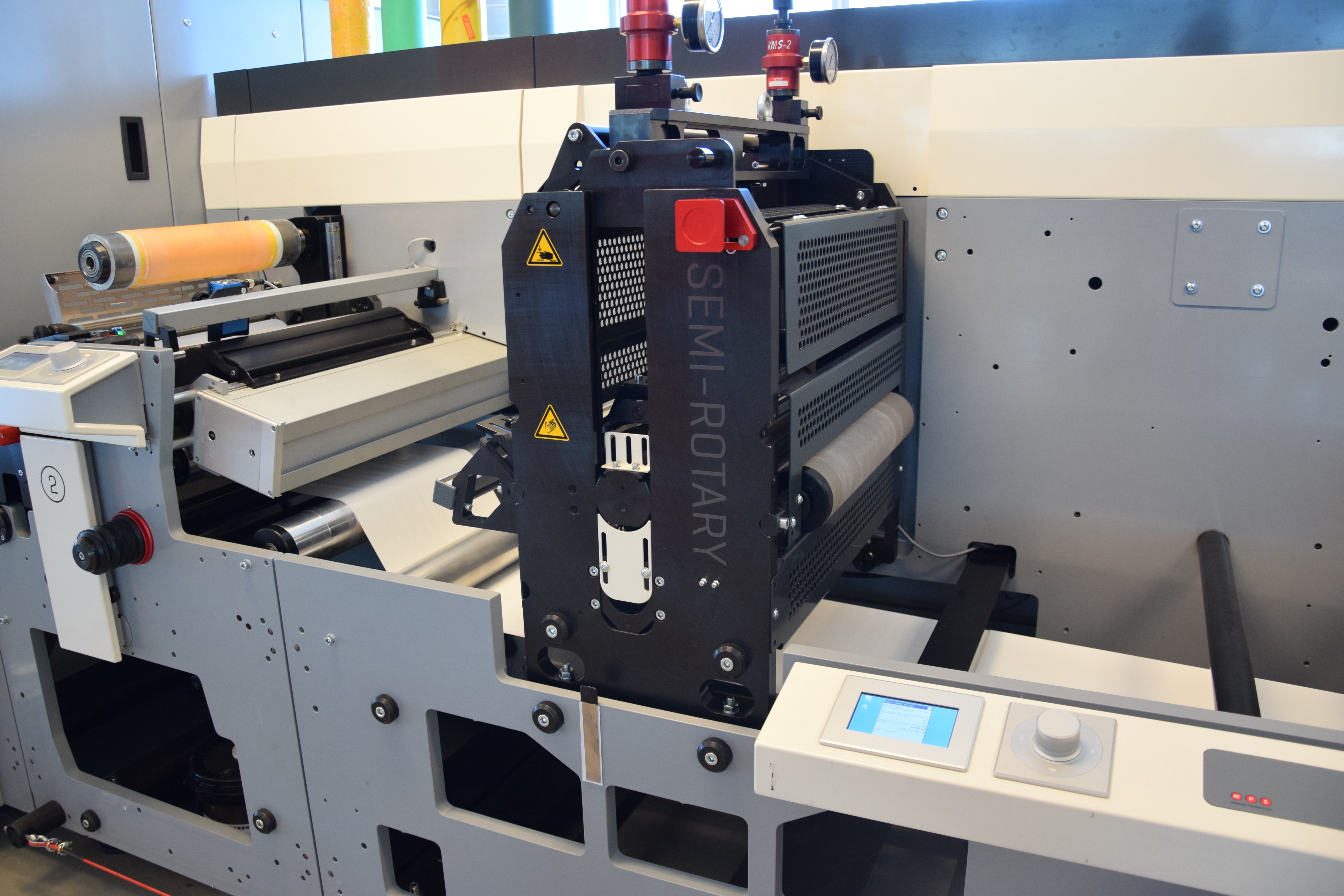

That’s true, but using a separate finishing line is expensive and the process takes time (plus, you’ll need two operators instead of just one). Presses with in-line finishing exist, like our own EF SYMJET. So why not take advantage of it?

an example of in-line finishing on the EF SYMJET: the semi-rotary die

an example of in-line finishing on the EF SYMJET: the semi-rotary die

One example of in-line finishing on the EF SYMJET press is this semi-rotary die-cut unit. I wrote another blog about The advantages of semi-rotary die-cutting on your hybrid printing press that you might find interesting to read.

Cost price

When printing a job, you make choices for the colours you use. For example, opaque white. When you print on transparent material, the white you’ll use will take a large surface, as behind the whole image you’ll need white ink. Based on cost price, printing this white colour would be much more beneficial in flexo, as this ink is less expensive.

Colour reach

With digital printing, you’re limited to a smaller and restricted colour spectrum: CMYK (cyan, magenta, yellow and key/black), violet and orange (and additional green). Sure, with these colours you can print a fair amount of colours, which is suitable for printing images, but there are a wide range of specialized colours and effects you just can’t re-produce on your digital press – such as metallic, certain pastels, fluorescent and neon shades, or when a customer requests ‘18-1659 TPG Goji Berry’.

This is where ink mixing comes in, with the range of pigments in flexo that are available, you can make any specific color, such as that Goji etc.

To sum up, both digital and conventional printing have many benefits. As a label printer, you want the best of both worlds to save time, money and be flexible for your customer. This is why a hybrid press is an ideal investment.We can tell you more about our EF SYMJET hybrid press, that combines digital with flexo technology.{{cta('2aaef802-c0d6-4640-9bb7-48d5f26bb664','justifyright')}}

If you want to know more about hybrid printing, feel free to contact me via h.poortinga@mps4u.com or download the free whitepaper about hybrid printing: