Growing demand for high-quality labels, customization and quicker lead times, shorter print runs and continual pricing pressure has led to a rapidly evolving label printing industry. And increased challenges for production leaders, too.{{cta('2aaef802-c0d6-4640-9bb7-48d5f26bb664','justifyright')}}

New printing technologies, like digital printing, have entered the market and continue to expand its presence. However, the industry is looking for ways to combine the benefits of both digital and conventional technologies.

As you can read in MPS' free whitepaper, hybrid printing has emerged as a solution that provides the best of both worlds.

What is hybrid printing?

In short, hybrid printing is combining several printing technologies and converting techniques in a single-pass process. It aims to merge the capabilities of conventional and digital printing methods, for example integrating the reliability, efficiency and in-line features of flexo printing with the creative possibilities of digital printing.

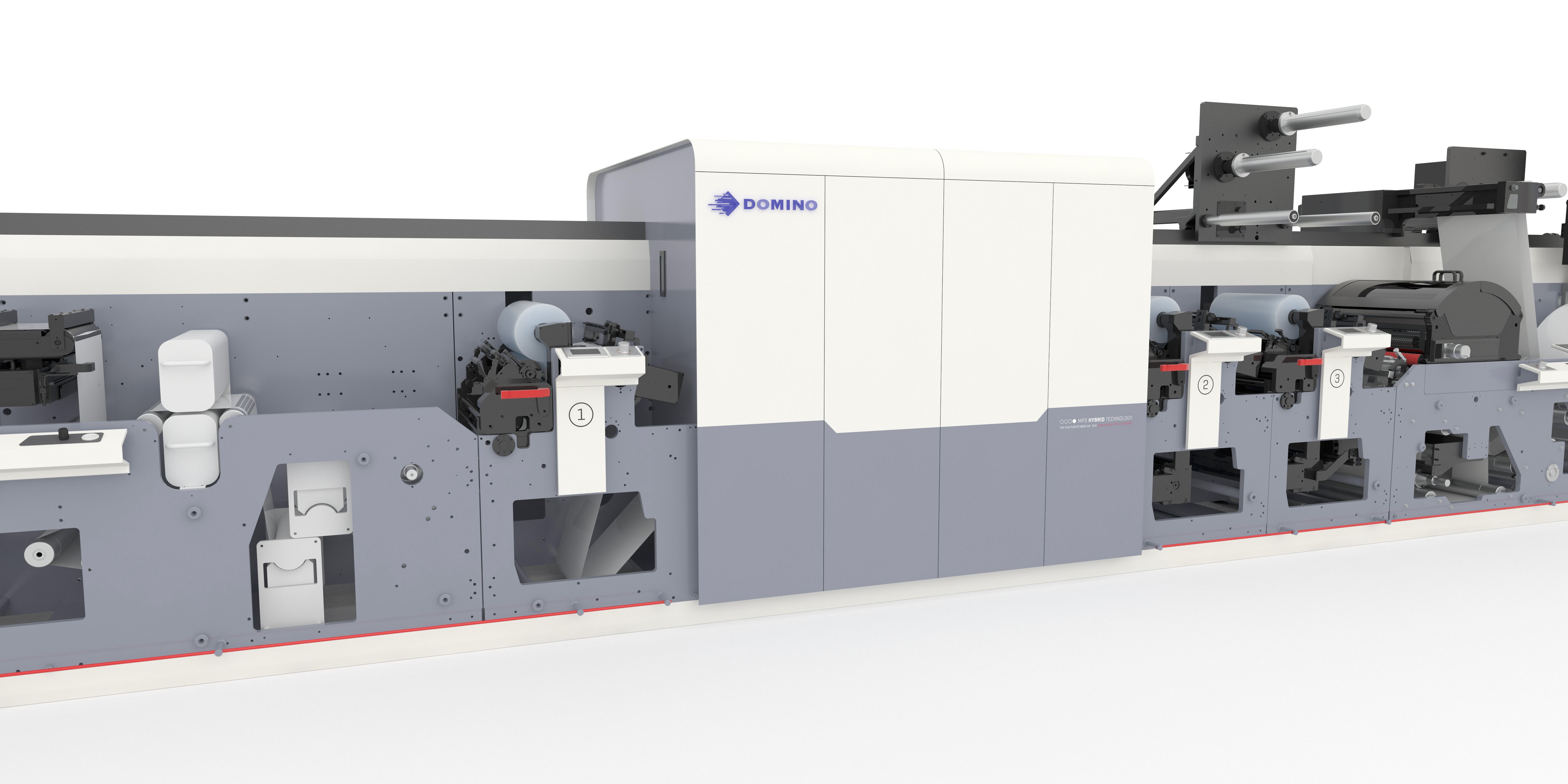

MPS EF SYMJET hybrid press that combines

MPS EF SYMJET hybrid press that combines

the MPS EF flexo platform with the integrated Domino N610i inkjet engine.

Key benefits of hybrid printing

To understand how hybrid printing is the future — and how it is strengthening the label printing industry, let’s take a look at four key benefits of this innovation:

- Serving a larger part of the market segment

Hybrid printing enables you to serve a larger part of the market segment because you can combine several printing techniques and utilize the advantages. For example, in flexo you can’t print variable data, and you can’t do cold foil in digital. With hybrid printing, you can do both.

Hybrid presses combine a suite of advanced features that enable you to customize print runs — and meet customer demands. The advantage? You can offer a wide range of applications and possibilities to your customers.

- Increased productivity

Due to the demand for quick lead times, it is crucial to make sure your printing process is as short as possible. Increased production is a key benefit of hybrid printing; it enables more work to be done in a shorter time span.

Most tasks within the printing process — printing, labeling, finishing, coating, and cutting — are done automatically. Also, hybrid presses can handle more jobs in less time. You’ll gain flexibility to print a larger number of short print runs or cut productions costs on large runs.

- Fail cost reduction and no semi-finished products

In many print shops, when several printing and converting techniques are combined, different machines are needed to print an end product. You have semi-finished products in stock of which you don’t know if the end product will meet the requirements.

To further explain: after each step an intermediate test is conducted, however only the final test will indicate if fault free quality is ensured. There is always a risk that things can go wrong, even in the last step. If a product doesn’t pass the test, you have to start over again. This increases costs and lead times.

if fault free quality is ensured. There is always a risk that things can go wrong, even in the last step. If a product doesn’t pass the test, you have to start over again. This increases costs and lead times.

In hybrid printing, you can print and convert labels in a single pass. After finishing a job, you can immediately see if the label meets the (quality) requirements. As a result, you reduce fail costs, and you have no semi-finished labels in stock.

- Easy scheduling and less prepress time

Because you only need one press to print an end product, imagine how scheduling jobs gets a lot easier. Also, hybrid printing requires less prepress time before you can start printing a job.

Why?

When you are limited to one printing technique, you need to make more adjustments in the prepress stage to get the quality that is required. When printing techniques can be combined, you can decide how you are going to run the job — based on quality and cost price. This makes the process easier.

Discover more about hybrid printing

Hybrid printing has — compared to using a single printing technique — even more benefits than described in this blog.

If you would like more information about this innovation, download our free whitepaper. You’ll learn more about the differences between hybrid, digital and conventional printing and how it compares from a time and cost perspective and what industry experts have to say among other things. It helps you to find out if hybrid printing is a viable solution for your business.

Download the whitepaper here:

{{cta('75f31875-db1c-44ac-abb6-add382e30948','justifycenter')}}

Did you know that the first chapter of the whitepaper is already online? It's last week's blog: When is a flexo/digital hybrid press a viable solution?